Introduction…

As Brabham, Tauranac and Denny Hulme scanned the competitive landscape as 1966 unfolded they formed the view that a similar formula to ’66 stood a good chance of success in 1967. A small, light, responsive chassis, this time designed around the engine. Remember that Jack’s successful ’66 mount, BT19 was an adapted, unraced 1965 GP car Tauranac designed around the stillborn Coventry Climax Flat-16. Ron’s ’67 BT24 was and is a superb car, its race record we shall review in an article about Brabham Racing Organisation’s (BRO) successful ’67 season.

In terms of the engine, keeping it simple and light had paid big dividends for Repco Brabham Engines Pty. Ltd. (RBE) in the first year of the 3 litre formula.

The fortunes of Ferrari, BRM, its H-16 engine the antithesis of the Brabham Repco’s in terms of weight and complexity and the Maserati V12 were well covered in my article on the ’66 season. Dan Gurney’s Weslake V12 engine showed promise but reliability continued to be an issue. The Ford Cosworth DFV didn’t race until the Dutch GP in June 1967. Brabham’s needed more power of course, too much power is rarely an issue, but they figured they needed less power than most others on the grid. If Jack and Denny started the season with a reliable, just quick enough package BRO could retain their title as others sought to make what were ultimately potentially quicker, more sophisticated multi-cylinder, multi-cam cars reliable. Click here for my article on Jack’s successful 1966 season; https://primotipo.com/2014/11/13/winning-the-1966-world-f1-championships-rodways-repco-recollections-episode-3/

The beautifully fast, light, forgiving championship winning Brabham BT24 Repco 740 ahead of Chris Amon’s Ferrari 312 at Le Mans during the ’67 French GP. Denny 2nd to Jacks winning sister car, Amon DNF with throttle linkage failure (Automobile Year)

They were an intensely pragmatic group of racers in this Brabham/Repco senior mix…

Repco’s Charlie Dean, Phil Irving, Norman Wilson (designer of the ’67 RBE740 Series V8) Brabham and Tauranac all built winning cars (and bikes in Phil’s case) themselves, as in built with their own hands. Dean created the extraordinary series of Maybach Grand Prix cars, look at my Stan Jones article for much detail about this series of racers built by Charlie and initially raced by him, and then later by Stanley with much success. Norman Wilson built a Holden engined special in his youth covered in brief at the end of this article. Tauranac and his brother Austin built and raced the ‘original’ Ralts before Ron joined Jack in the UK in 1961.

Dean, Wilson, Tauranac and Brabham had been/were drivers. They knew what it took to win races. They understood winning was as much about torque as power. Handling was essential, the circuits then were all far from just requiring top end power, what was needed at Monza was different to the blend of corners and contours at Brands. All had driven cars and lost races due to unreliability. They understood a balanced package was critical, that whatever power they had needed to be put to the road. The point I make is that these guys were practitioners not theorists on ‘an engineering jolly’.

The RB group were about the application of sound pragmatic engineering practice, they didn’t have to think deeply about this stuff it was part of their DNA given the ‘build and develop it yourself’ school from whence they came. These guys weren’t ‘university engineers’ (which is not to say they lacked formal qualifications) but very practical chaps. Let the others chase ‘engineering perfection’ as they saw it, ‘an evolution of what we have is probably enough to do the trick’ was the correct thinking.

It was a whole different ballgame they confronted at the same time in ’68, but this was mid-’66, the game-changing DFV was still a distance away…

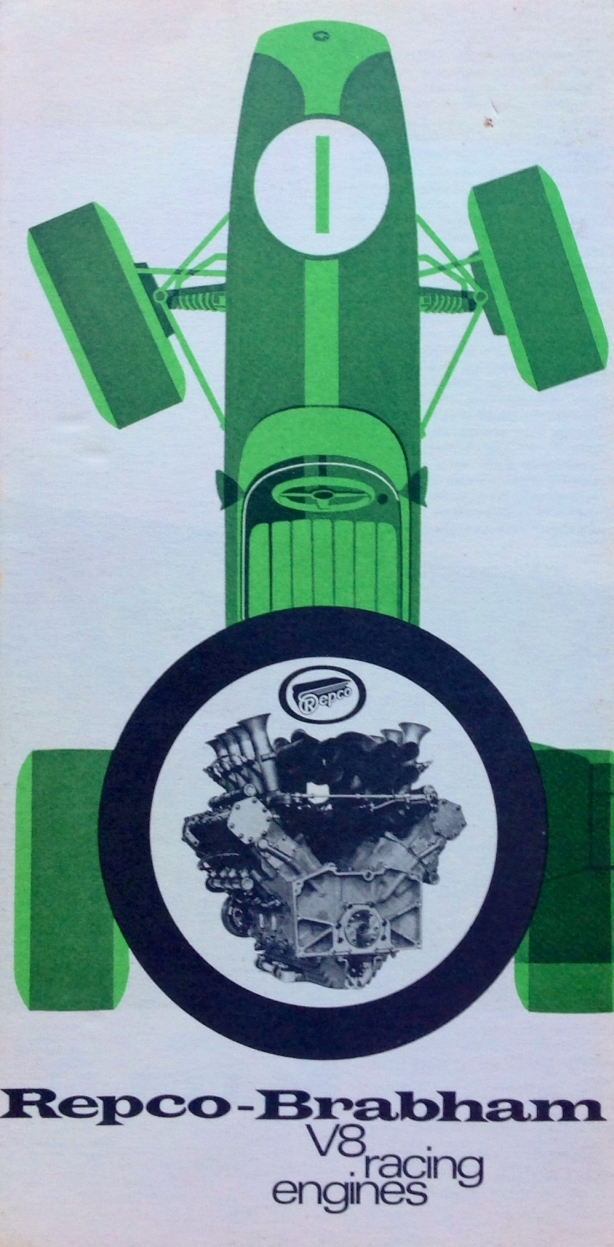

Repco studio shot of the front of the amazingly compact ’67 championship winning ‘RBE740’, SOHC, 2 valve ‘between the Vee exhaust’, circa 330bhp V8. The ‘mix and match’ of engine parts described in the text is proven by use of 620 water pump, 630 chain timing cover, oil filter American ‘Purolator’, note oil pump below the dry sump pan, and up top the ends of aluminium water cooling rails, Bosch distributor and Lucas fuel injection trumpets (Tait/Repco)

1967 Engine Design Deliberations…

Ex RBE Engineer Nigel Tait; ‘By July 1966 the World Titles had already been ‘wrapped up’ for the year so the team were already thinking about the engine for 1967. Phil, Jack and Ron were all keen on the idea of getting the exhausts out of the airstream to clean up the car in terms of better aerodynamics and also for ease of plumbing the exhausts which otherwise had to negotiate the tubular chassis frame’. The 1966 BT19 championship winning chassis did not present a very effective frontal profile, its exhausts well out in the breeze.

Colin Chapman was far from the first chassis man to be prescriptive about design elements of an engine, as he was to Keith Duckworth in relation to the Ford Cosworth DFV, particularly in relation its integration with ‘his’ chassis.

Between the Vee exhausts had been raced successfully by BRM with its P56 1.5-2 litre family of V8’s in recent years. Ferrari also chose the same approach with its ’67 3 valve V12, its fair to say it was an F1 design trend of the time. In some ways Ferrari’s approach was better than Brabham’s as Ron maintained outboard springs and shocks on both the front and back of his ’67 BT24 chassis. Ferrari, as they did in 1966, used a top rocker and inboard front spring/shock presenting less resistance to the air at the front of the car at least. Ferrari went outboard at the back like Brabham. (and the rest of the grid)

Old and new; ’66 RB620 305 bhp V8 left and ’67 RB740 330 bhp V8 right, F1 champions both. 740 was 3 inches shorter, 4 inches wider across the heads and 15 lbs lighter than 620. Dimensions otherwise the same; 25.5 inches long, 17.25 inches wide across the bellhousing (Repco)

Conceptual Design of the Heads…

RBE Chief Engineer Norman Wilson; ‘ It would have been Jack’s idea to put the exhausts in the centre (of the Vee). Jack asked if it could be done. I remember when i started designing them i spent a lot of time, probably 3 or 4 days, just drawing one cylinder up to try and prove that you could fit everything in. See you have got a whole row of head studs, you have got to have water passages between the port. The whole idea was to prove that you could get the inlet port in, exhaust port and all the head studs. That was a giant task to figure out in a way’.

‘It meant putting the outer row of studs underneath the exhaust ports. I don’t think i have the layout now but i remember spending a huge amount of time and finally i went to Frank Hallam (RBE General Manager) and said i think we can do it. And thats how the 40 Series heads started’. ‘To manage to get everything on one side and the thing is unlike most engines we built as we wanted big ports. So to fit all these big ports in plus the port wall, plus the bolt bosses was a major task. I think it took about three days work for me to fit everything in a rough layout’.

Jack’s BT24 Repco 740 being fettled during ’67, circuit unknown. ‘Box is 5 speed Hewland DG300 transaxle, note rubber ‘donuts’, Lucas injection ‘bomb’ or fuel pump to the right of the box, also rear spaceframe chassis diaphragm. Getting the exhausts outta the airstream shown to good effect in this shot (unattributed)

The ’40 Series’ Between the Vee 1967 Cylinder Heads Design Detail…

‘…the new cylinder heads retained parallel valves but they were now in line with the cylinder axis (instead of at 10 degrees to the axis as on the ’66 20 Series heads and were flush to the head face’ said Wilson. ‘The 40 Series heads used the Heron head design. In this design the cylinder head is flat and the piston has the combustion chamber in the top of the piston (a bowl in piston arrangement). The other feature of the 40 Series head is that it had a tall inlet port. It had a fairly long, relatively straight section there on Jack Brabham’s suggestion. He had received some highly secret information from Honda that this was the way to go. In hindsight i don’t think so. All these things are better in hindsight, but that’s how we did it’

‘The Heron head, i think everyone agreed, had to be the way to go because the Cosworth SCA (F2 engine) was 1000cc and was putting out 120bhp. At the time in F2 it was winning everything. I think it put out 123bhp. Now if you are looking at a 3 litre engine, thats 369bhp. And at that time that would have been been looking for us a fairly exciting sort of figure. The other point about the Heron head is it allowed us to have a single camshaft which we wanted to have the low weight, simplicity and ease of manufacture’.

‘The 40 Series head was purely made for the car. No other reason. It put the exhausts down the centre of the Vee…thats what Ron wanted, he made the car so why not get what he wanted’.

‘The highest output of the 740 Series 3 litre was only a bit over 330bhp. This horsepower rivalry between the different engine manufacturers at the time, the horsepower numbers were really irrelevant. At the time Maserati claimed about 500bhp, but they were adding on about 100bhp to make up for the exhaust gas pollution in the test cell. But really its about the area of horsepower curve’. ‘If they had 500bhp they would be leaving us behind a lot quicker than they are leaving us behind!’ was a quip Rod Wolfe recalls Jack making to the boys in the RBE engine assembly area on one of his trips to Australia in 1967.

‘One of the philosophies was for the engine to always have a wide power range and good power at the bottom end of it which suited the light car. So if ours was 330bhp there was no way other cars had 400-500bhp claimed. Our power was distributed much more evenly across a wider range of revs. Thus Denny Hulme would say it was great to drive a Repco Brabham because he could overtake competitors in the corners as if they were ‘tied to a fence’.

There were some problems with 40 Series head porosity during ’67 as ex-RBE machinist/storeman Rodway Wolfe recalls; ‘Norm did a fantastic job to even succeed with the casting and it proved to be a great engine in larger capacity too, bigger valves etc…we were able to fit very large valves without too many seat problems. The 40 series did have a lot of porosity problems with the ports, some we scrapped as the ports actually broke through when we were porting them and there was not the welding equipment available that we have nowadays to repair them. Porosity, a big drama, as i say, one of my jobs was to send the castings to ‘Nilsens Sintered Products’ in Richmond where they placed the heads in a vacuum and impregnated them with hot resin. Vacuum impregnation solved some of these problems’.

Brabham on the Warwick Farm grid, WF Tasman round in 1967. In relation to the cooling duct feeding the engine Rodway Wolfe comments ‘There were a few heat problems in the valley of the engine with the 40 series as the fuel metering unit was also located in the valley but small heat shields seemed to correct this problem and it was not an issue once the car was on the track of course’. It seems these ducts were used in the ’67 Tasman rounds on the 640 engines used by Jack and Denny and subsequently sporadically on the 740 engines, Le Mans for example (Bruce Wells)

A typically pragmatic decision to the heads was made in relation to the 1967 Repco block…

Remember that the ’66 engine used a heavily adapted version of the Oldsmobile F85 aluminium block. Repco still had a swag of unused blocks sitting in Rod Wolfe’s Repco store at Maidstone. The blocks had been successful, a world title proof enough of their effectiveness, but the machining and adaption required to make them an effective race tool meant they were expensive but still sub-optimal. But it wasn’t all plain sailing with the block however much it may have seemed so from the outside, Tait; ‘For much of 1966 we had serious blowby issues due to distortion of the dry sleeves and it was not until almost the end of that year that we went to wet sleeves. The F85 Olds blocks came with dry sleeves in situ’.

Repco’s race engine commercial ends were to be served by building and selling engines for Tasman use and for Group Seven sportscars, burgeoning at the time globally; 2.5 litres was the Tasman Formula capacity limit, the F85 ‘maxxed out’ at 4.4 litres which was the capacity used for the sportscar engines. Repco’s first sale of a customer engine was the 4.4 litre 620 Series unit sold to Bob Jane for his Elfin 400.

So Repco decided to ‘have their cake and eat it too’. The new bespoke ‘700 Series’ block would allow all of the F85 ‘600 Series’ bits and bobs to attach to it; heads, timing case, sump the lot. So Repco could gradually use its stock of F85 blocks for Tasman and sportscar use whilst ‘700 Series’ blocks were used in F1 for 1967 and more broadly in capacities up to 5 litres subsequently. As engines were rebuilt the 600 blocks were replaced progressively by 700 series units, 600 blocks ceased to be used when there were none left. Typically practical, sensible and parsimonious Repco!

Whilst the ‘700 Series’ block design decision, to allow 600 hardware to be attached was a ‘functional’ pragmatic decision the aluminium block itself was also improved being redesigned to increase rigidity. The new block design was commenced by Irving, he and others say, prior to his departure from RBE, but the completed block is his replacement as Chief Design Engineer, Norman Wilson’s design.

The post Phil Irving RBE design team; L>R GM Frank Hallam and Engineers Norman Wilson, Lindsay Hooper, John Judd and Brian Heard (Repco)

Phil Irving’s departure by resignation or sacking by RBE GM Frank Hallam is an important part of the RBE story and will be dealt with in a separate article. I explore not just the difficult relationship between these two characters but also the broader issues of the leadership of Repco, CEO Charles McGrath’s key enduring support of the RBE program and the appointment of Bob Brown as the Director responsible for RBE instead of alternatives including Charlie Dean at the projects outset. The antipathy between Hallam and Irving was partially about personality but also about politics and legacy in terms of who is responsible for what of the RB620 design and build. More on this topic very soon.

For now lets just focus on the RB740 engine which in no way shape nor form was negatively impacted by Irving’s departure…whilst noting that their probably would have been no 740 had it not been for the success of Jack and Phil’s RB620, JB as the engines conceptual designer and PI as its detail designer and draftsman…

Norman Wilson; ‘When i went there (to RBE from Repco Research) John Judd (who had been seconded to Repco by BRO in the UK) had done a new crankcase. So i asked to look at it and John showed it to me and i said we can’t make it. It was impossible because it was the basis of a whole new engine. It became a mutual decision (by the design team) that we make a crankcase that went underneath, on top of and behind exactly what we had’. ‘We couldn’t have made a crankcase, head and timing case all at once. So we made a crankcase and then we did the 40 series heads. We had to have a timing case with the heads but it meant we didn’t have too much to do at once and we just kept progressing’.

Wilson;’The new crankcase was designed from scratch but was also designed so it could accommodate the 20 series cylinder head if we wanted to. It was critical being a fairly small outfit that we had the maximum amount of interchangeable flexibility between all the components that we made. So the 700 series crankcase was designed to overcome the problems that we had seen or experienced with the Oldsmobile F85 600 series crankcase. It had wet liners, that in part was due to the fact that it was easier to cast the cylinder block with a wet liner design in that it simplified dramatically the coring required for the casting of the block’.

‘The Oldsmobile engine showed it had main bearing problems so we altered the main bearing arrangement to be much more rigid. We extended the studs up through into the centre of the Vee with nuts on top to take some of the load up through to the top of the block. The unfortunate part of that was the design was right but people would always do the nuts in the top up tight. And of course what would happen was the cylinder block being aluminium would expand more than the stud and would eventually break it. What they should have done, and no one would listen, was do them up at a much lower torque so when the engine got hot it would put the right load on the stud’.

RBE Boys, Maidstone, undated but circa 1966/7. Back L>R Kevin Davies, Eric Gaynor, Tony Chamberlain, Fred Rudd, John Mepstead, Peter Holinger. Middle; Vic Mosby, Howard Ring, Norman Bence. Front; David Nash, Rodway Wolfe, Don Butler (Tait/Repco)

‘The front bearing panel of the block was made stronger because this had proved to be a weakness with the Oldsmobile block. The back of the block was made with the same stud pattern as the Olds block so that all the existing gearbox adaptors could be used. The block was made with the idea of making it as light as possible and that was one of the critical things in design. In the end Frank suggested we put some diagonal ribbing on the 700 series crankcase walls to strengthen them’. ‘The sidewalls of the crankcase were actually bolted to the main bearing caps…cross bolting (and strengthened the crankcase considerably). So i felt the diagonal ribbing was really quite irrelevant. …Frank wanted it and, you know, he was a pretty good boss to work for, so thats what we did’.

‘The other thing about the block was that later when we made the 4.2 litre Indianapolis engines (760 Series DOHC, 4 valve V8 in 1968/9) we could alter the sealing arrangements, in fact the later F1 engines (’68 860 Series) were the same, so we used Cooper rings instead of head gaskets. Cooper rings sealed the combustion chamber and O rings sealed the water passages. But we also then had a groove around the outside of the Cooper ring joined with a shallow slot to the edge of the head so if one Cooper ring leaked slightly there was no way it would pressurise the cooling system’.

‘With the Indianapolis engine (760 Series 4.2) those grooves came out of the inside of the Vee. So you could run your engine in the pits and you could put your finger over the end of each groove and you’d know if any of the Cooper rings were leaking slightly. The 700 block was the same height as the Olds F85 block. And the 800 block (860 F1 and 830 Tasman 2.5) was a (1.5 inches) lower one to make the engine smaller.’

The 700 Series block apart from being stronger was also 15 Kg lighter than the F85 ‘600 Series, Norman Wilson again; ‘The F85 block was designed to be diecast on a diecasting machine, it was perhaps a bit thicker in spots just to make it easier to cast. We got rid of a considerable amount of aluminium around each cylinder…The Repco block didn’t have all the bosses down the centre along the block for the cam-followers. It didn’t have the cam-bearings for the centre camshaft (of the F85) We didn’t have the stiffener plate on the bottom. The bearing caps were bigger but they were done a bit better and they were probably no heavier than what was there. And in all the places where strength was not required we just skinned them down as much as we could’.

Most of the components for the engine were made by Repco subsidiary, Russell Engineering, few were contracted out.

Wolfe; ‘Most of the RBE engine components were made at the Maidstone factory. The pistons and rings however were other Repco companies and the crankshafts Laystall in the UK but no other F1 engine constructor made their own pistons and rings in 1966, even Ferrari used Hepolite pistons so Repco were unique’.

Harold Clisby’s engineering business in South Australia cast many of the heads. Kevin Drage, the senior engineer at Castalloy, the Clisby subsidiary who made the heads recalled that around 120 cylinder heads of four types’ 30,40, 50 and 60 Series were cast by the company over the period of the RBE program.

The 30 Series head was detailed by John Judd and was two valve with inlet and exhaust ports on either side of the head, ‘crossflow’ inlets between the Vee and exhausts out the side. 40 Series (the ’67 championship winner) heads were detailed by Norman Wilson which had inlet and exhaust ports on the same side of the head, between the Vee exhausts.

Drage recalls that; The two valve 30 and 40 Series heads were soon followed by the four valve 50 and 60 series designs. John Judd drew these up with the 50 Series design having diagonally tangentially ported inlet and exhaust valves resulting in 16 inlet trumpets and 16 exhaust pipes, the 60 Series design having siamesed inlet and exhaust ports’. The 50 Series heads which were built and dyno tested and the 60 Series 1968 F1 4 valve, DOHC design are a subject of a future article. The fact that RBE persevered so long, at GM Frank Hallam’s insistence with the 50 Series heads delayed development of the 60 Series design, to RBE and BRO’s cost during the ’68 F1 season.

The Commonwealth Aircraft Corporation at Fishermens Bend, not too far from RBE’s Maidstone factory made the alloy crankcases and timing covers, note that Wilson went to double-row timing chains with RB740 compared with the single chain of RB620.

Ex-Repco engineer George Wade is often given credit for the camshafts but Rod Wolfe says; ‘we made the camshafts for all of the engines, George Wade profiled them to various specs but we turned the billets with a mimic tracer on our Tovalieri lathe. The very first 620 cams were cast iron but were changed to steel in 1966’.

Lucas fuel injection was of course again used, as well as a Bosch distributor.

Summary of RBE740 F1 3 litre engine specifications/suppliers…

Bore/Stroke; 3.5X2.55 inches, capacity 2996cc. Power 330bhp@ circa 8400rpm, weight 350 pounds

Compression ratio 12:1, valve sizes 1 13/16inches inlet /1 1/2 inches exhaust, valve angle vertical, valve lift .40. Valve timing 50, 70, 50, 70

Pistons, rings and main bearings by Repco, big end bearings supplied by Vandervell

Lucas fuel injection, Bosch coil and distributor, Champion plugs, Esso fuel and oil and Borg and Beck clutch

Denny Hulme DNF ignition and Jackie Stewart 2nd in their ‘between the Vee’ exhaust Brabham BT22 ‘640 Series’ Repco and BRM P261 respectively Levin, NZ 14 January 1967 (Digby Paape)

Racing the 640: 1967 Tasman Series…

The first race of the 1967 GP season was the South African GP at Kyalami on January 2, Jack and Denny raced 620 Series V8’s, the 740 was running late due to delays in patterns being made for the 700 crankcase. Its an interesting observation given that Hallam told Brabham by letter dated 23 September that the 700 patterns were half finished. In any event, the engine was late so made its debut in the Tasman Series, or more specifically 640 Series engines did; the new heads atop the 600 Series/F85 Olds blocks.

Brabham giving his 620 engined BT20 some welly at Kyalami during the South African GP at Kyalami on 2 January 1967, he was 6th from pole with Denny 4th from grid 2. Pedro Rodriguez won in a Cooper T81 Maserati (unattributed)

RBE staff numbers during the Christmas/New Year 1966/7 period swelled to 37, 23 engines being assembled during this period. Frank Hallam records that due to the great amount of dismantling, assembly and experimentation that took place only four 2.5 litre motors raced in the Tasman Series. The 640 series 2.5 litre Tasman engines gave circa 265bhp@8500rpm.

Brabham’s full ’67 F1 season i will cover in a separate article, here we look at the Tasman races for the 640 and early season F1 races of the 620 and 740.

RBE’s Michael Gasking and BRO’s Roy Billington and another mechanic prepare Brabham’s ‘RB640’ 2.5 V8 engined BT23A before the Sandown Tasman round on 26 February 1967, DNF ignition. Repco Maidstone factory (Wolfe)

If you take the view that the ’67 Tasman was a warm up for the ’67 World Championship then it was a success for Brabham and RBE. The 40 Series heads were thoroughly race tested during the annual Australasian summer contest.

Equally important was Jacks mount, his car designated BT23A was an adaptation of Ron Tauranac’s very successful new 1967/8 BT23 F2 design, which won dozens of races in Ford Cosworth FVA 1.6 litre F2 spec. The Tasman BT23A was effectively the prototype of the BT24 which went on to win the ’67 titles, so the Tasman ‘blooded’ both the chassis and engine well before the F1 season. The reliability which flowed from this development process won RBE and BRO the ’67 championships, the Lotus 49 Ford Cosworth DFV was well quicker but had not had the development miles the Brabham Repco’s had…

Jim Clark took the 1967 Tasman title in an F1 Lotus 33 fitted with a stretched to 2 litre Coventry Climax FWMV V8 engine, a quick, reliable, well proven combination. Clark took 3 wins, Jackie Stewart 2 in a similar F1 BRM P261. But the stretched to about 2.1 litres P56 V8 stressed the BRM transmission to its limits, the ‘tranny its weakness that summer. Jack was equal 3rd on the points table to JYS with 1 win.

Jack and Denny contested all rounds of the championship with the exception of Teretonga, the last Kiwi event. Jack took a win at Longford and Denny 3rd at Wigram his best. Brabham had a lot of unreliability but the problems weren’t in the main engines; for Denny a radiator hose at WF, gear selector at Sandown and electrical problems at Longford and for Jack a driveshaft breakage at Teretonga and ignition dramas at Sandown.

At that stage Repco hadn’t sold customer Tasman 2.5 engines of any type, the engines were made available later in the year in time for commencement of the domestic Gold Star series (640 & 740 Series 2.5 V8’s) in the meantime the more important business of getting the 3 litre ‘740 Series’ V8’s into Tauranac’s exquisite little BT24 was the priority.

Jack from Denny in BT20’s; Jack’s 740 engined and Denny’s 620, Denny won both heats and Jack the final giving the 740 the first of its many wins in 1967. Oulton Park ‘Spring Cup’, 15 April 1967 (Brian Watson)

The first F1 event of the European ’67 season was the Race of Champions at Brands Hatch on 12 March.

Dan Gurney won both heats and the final in his Eagle T1G Weslake, Jack was 9th a ’66 spec 620 engined BT20 with Denny DNF, similarly equipped.

The ‘Daily Express Spring Cup’ at Oulton Park followed on 15 April, Brabham ‘cleaned up’ in BT20’s; Denny won both heats and Jack the final taking a great race win for the new 740 3 litre V8 with Denny 2nd in a 620 engined ’66 chassis.

Jack proved the speed of the new RB740 V8 at Monaco, its championship race debut, plonking it on pole but it went bang with a broken conrod in the races 1st lap, car is Jack’s beloved ‘old nail’ Brabham BT19, his ’66 championship winning chassis. Denny won in ‘last years’ quick and reliable BT20 Repco ‘620’ (unattributed)

BRO fitted its first 740 Series engine just in time for the Monaco GP on May 7.

Apart from the delays caused by late patterns for the blocks, Repco Die and Tool Co forged conrods developed faults. After being unable to establish why the Repco rods were failing the team went the Carillo route, the team using these tried and true products…despite not being made in Oz! Rod Wolfe; ‘We did discover that the champfer at the bolt heads did not match the bolt radius under the head of the bolt and even when tensioned correctly they were not seating properly resulting in a couple of failures’.

The definitive RB ‘740 Series’ engined Brabham BT24 didn’t appear until Jack gave the chassis/engine combination its championship debut at the Belgian GP, Spa on June 18. This was 2 weeks after the Ford Cosworth DFV V8 took the first of 155 GP wins, the 1967 successful Brabham GP season a Repco story for next time…

‘Black Jack’ at La Source during the ’67 Belgian GP. Both he and Denny retired with engine problems in BT24 and BT19 respectively. Dan Gurney took a famous and well deserved win in his Eagle T1G Weslake V12, 18 June. Compact nature of the F2 derived BT24 clear (unattributed)

Repco 1966/7 promotional film…

Check out this great footage, the first half covers Brabham’s victorious 1966 F1 season, the other bit the ’67 Tasman season, the debut of the 640 Series V8’s including some factory footage of the engines build.

Etcetera…

Rodway Wolfe ‘The dyno test house at the rear of the Repco Maidstone factory. The silver drum on the side was the fuel tank which was changed when needed. The walls of the building were very thick…when the engines were running at full noise you could hold your hand against the wall and get a massage! Fascinating!’ (Wolfe)

Roy Billington and Denny Hulme in the middle of a ratio change in the Wigram paddock. Note the Brabham BT22 Hewland gearbox, high pressure Lucas ‘bomb’ fuel pump and 640 engine of course (J Manhire)

Repco 640 2.5 V8 power; Jack all cocked up in Warwick Farm’s Esses during the AGP, Warwick Farm 19 February 1967. Brabham was 4th in his BT23A, Stewart won from Clark and Frank Gardner in BRM P261, Lotus 33 Climax and Brabham BT16 Climax respectively (unattributed)

Repco works Brabham Repcos’ on the move, Tasman Series, Longford, Tasmania 1967. ‘Rice Trailers’ the ducks guts at the time, tow cars are Holden ‘HR’ Panel Vans, 3 litre straight OHV 6 cylinder engines and ‘3 on the tree’ column shift manual ‘boxes (Ellis French)

Sandown Tasman, 26 February 1967, Brabham, Brabham BT23A Repco, Stewart BRM P261 and Hulme on the outside, Brabham BT22 Repco, all DNF! Jack with ignition, Stewart crown wheel and Hulme gear selection problems. Clark won in a Lotus 33 Climax. You can see the ducts directing cooling air between the Vee shown in an earlier shot (unattributed)

Jack hooks into the Viaduct ahead of Jim and Denny in David Chintock’s impression of the ’67 Longford Tasman round which Brabham’s BT23A won (Wolfe/Racing Car News)

Etcetera: Norman Wilson RBE740 Chief Designer…

Its interesting context to Wilson’s work at Repco Brabham Engines to look at the car he built as a ‘youngster’ before his ‘glory years’ as part of the Maidstone team. The car is both innovative and practical in its adaptation of proprietary parts, a combination applied in his later work.

As the cars current owner Greg Smith observes ‘the Norman Wilson Special is a beautiful study of a late fifties racing car with its Mercedes’ styling and layover engine, side vents and knock-off wire wheels’

‘Norman Wilson Spl’ in the foreground at Templestowe Hillclimb in then outer eastern Melbourne. Pat Hawthorne’s Lycoming Spl behind. The carbs are Webers, sidedraft right angle alloy castings (Greg Smith)

Norman started his 6 cylinder Holden engined ‘Norman Wilson Spl’ around 1956 aged 29/30. The chassis is a spaceframe, front suspension Wilson’s using inverted Holden uprights and wishbones, his own cross member and geometry. Steering is rack and pinion. The rear end is a ‘cut and shut’ Holden with an offset diff to lower the driver, springs are quarter elliptics with some neat locating links.

The clever bit was laying the Holden engine over at 30 degrees to the horizontal to both lower both the centre of gravity and bonnet line. By the time the car was finished Norman had moved to Repco, where it was completed and furnished with 3 large, single throat Webers Charlie Dean bought for Maybach but never fitted to it when that car was fuel injected. The ‘box was Jaguar, the beautiful aluminium body built by Barry Hudson who also did the Ian Mountain (Peugeot) Spl.

Norman raced the car, mainly in Victoria from 1960-63, it passed through several hands before being ‘chopped up’ in the late ‘60’s. With the interest in historic racing growing, and knowing the historic significance of the car and driver, reconstruction was commenced by Graemme Brown in Adelaide in the mid 1980’s, its first run in 1997. The car is currently being rebuilt by Victorian racer, engineer and raconteur Greg Smith to its precise period spec from whom this history and photos were provided. There is a whole lot more to this incredibly clever car built by Wilson in his youth, we will do a feature on it when Greg is close to its completion, I’ve seen it, the thing is sensational, Smithy will race it during 2017. I also plan to write more about Norman Wilson’s career, too little is known about this fella, now 91. so important in the Repco story.

Bibliography…

Recollections of Rodway Wolfe and Nigel Tait

Norman Wilson quotes from Simon Pinder’s ‘Mr Repco Brabham’, Doug Nye ‘History of The Grand Prix Car’, ‘Phil Irving: An Autobiography’

Kevin Drages comments from ‘The Nostalgia Forum’

Greg Smith’s photos and details of Norman Wilson and the ‘Norman Wilson Spl’

Photo Credits…

Rodway Wolfe and Nigel Tait Collections, Repco Ltd archive

Autocourse, Digby Paape, David Keep, Bruce Wells/The Roaring Season, David Keep/oldracephotos.com, Automobile Year, Ellis French, David Nash, John Manhire

Tailpiece: Jack Brabham guides his Brabham BT23A Repco into the Viaduct on his way to victory in the ‘South Pacific Trophy’, Longford 5 March 1967. He takes the first of many ’40 Series’ Repco 1967 wins…

Finito…

howard ring and don butler are two of the people in the group photo

Many thanks John, Rodway Wolfe gave me your details ages ago, I tried to get in touch to get your broader Repco perspective and SR4 experiences in particular whilst doing that piece with Nigel. My email address is mark@bisset.com.au and mobile is 0419 332342 if you would like to share your recollections. The SR4 piece is incomplete without you! Mark

thanks mark happy to catch up ,do you have a contact for rod ,I don’t have current contact,cheers john

John, happy to put you in touch with Rodway, and thanks for the call the other night, will call you back, just a busy couple of days! Am very keen to talk to you, Mark

Hi Mark,Gordon Littleford here. I wrote to you a while ago about my time with Repco Brabham but as yet haven’t heard back from you. Did you receive my emails? If not let me know and we’ll try again. Gordon Littleford

Sent from Yahoo Mail on Android

Gordon,

Happy to run your recollections, I attended a reunion of about 40 of your former RBE colleagues a month ago in Moonee Ponds not too far from the old Maidstone factory, so I have a swag of material to progressively write about/upload .

If you are into Facebook, key ‘Repco Brabham’ into the FB search engine to join the group, several of us are trying to get all of you guys using that means of regular communication/yarn swapping etc.

In terms if your own stuff email me please; mark@bisset.com.au

Thanks for following me up,

Mark

[…] https://primotipo.com/2016/08/05/rb740-repcos-1967-f1-championship-winning-v8/ […]

Great article Mark on the 740 series Repco Brabham V8. Accurate in every way and a fantastic work of history. Your ability to write so accurately about events half a century ago is to be commended. Thank-you on behalf of myself and my former fellow workmate for getting such a difficult story right.

Thanks Rod,

I’ve got one ready to go on the Tasman 2.5’s, just got photo captions to do- I must finish it! All of your archives and guidance around some of the tricky stuff is key- I think between us we are getting it right. I’m much busier on the work front this year so am behind in seeing people like Meppa! See you next time you are in Melbs.

Mark

[…] https://primotipo.com/2016/08/05/rb740-repcos-1967-f1-championship-winning-v8/ […]

[…] https://primotipo.com/2016/08/05/rb740-repcos-1967-f1-championship-winning-v8/ […]

With a bore of 3.5″ and stroke of 2.55″ capacity would be 3216cc. A stroke of 2.375″ would give the quoted capacity of 2996cc.

[…] There was only so much Repco Brabham Engines could do with the SOHC 740 Series V8, they were busy just keeping up with routine rebuilds for the two BRO cars. As the year progressed the Maidstone, Melbourne crew explored the 850 radial-valve V8 as their ’68 F1 engine, and then, having spent way too much time flogging that dead-horse, on the definitive, but way-too-late 860 DOHC, four-valve V8. Click here for a piece on the RBE740; ‘RB740’ Repco’s 1967 F1 Championship Winning V8… | primotipo… […]