Peter Macrow gives a row of poplars a fright as he runs wide at Newry corner during the March 1968 Longford Tasman Cup weekend, Argo Chev V8.

The Argo is a special built from the bones of an uncompetitive Cooper T53 by Ray Gibbs, a Melbourne racer/mechanic who had a stint at Cooper in his CV, for grazier/racer/car owner Tony Osborne.

With a too-long-to-be-competitive gestation period, it was first raced by Ian Cook in 1967. When Ian bagged a drive with Bob Jane Racing, another Melbourne up and coming single seater pilot, Peter Macrow got the ride. See here: https://primotipo.com/2023/05/01/cheetahs-riverina-gold-cups/

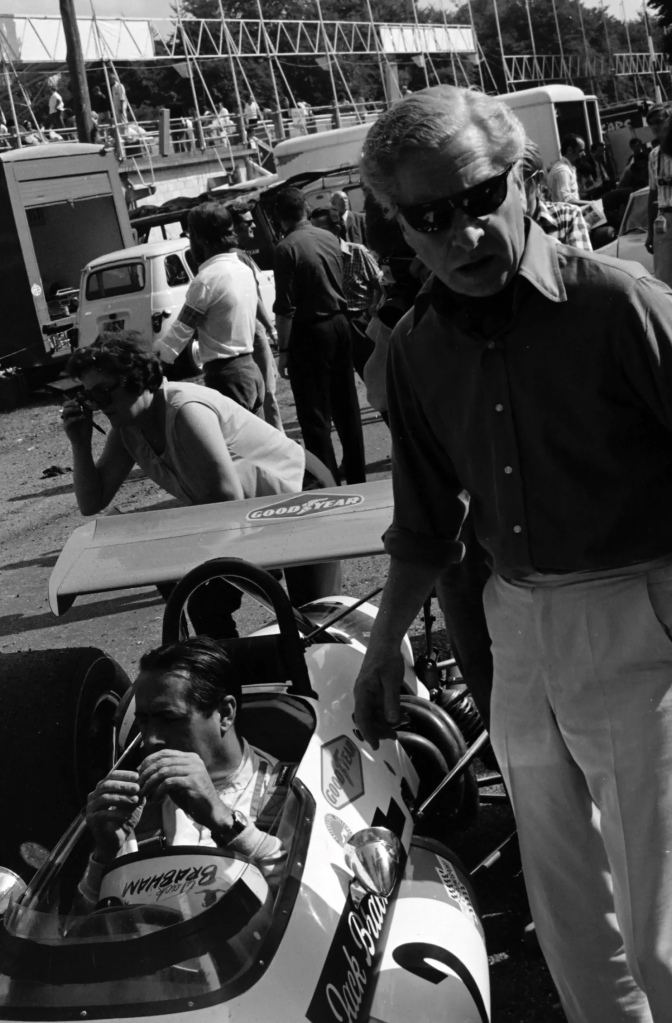

Look how those trees have grown! They were saplings when Jack Brabham and Bib Stillwell raced each other on the same stretch of road out of Newry, in the Longford Trophy eight years before.

The freshly minted World Champion won there in 1960 aboard a Cooper T51 Climax 2.5 FPF, from the similar chassis of Alec Milden and Stillwell. Alec’s car was powered by a Maserati 250S four, Bib’s by a 2.2-litre Climax FPF.

Click here for a feature on this meeting: https://primotipo.com/2015/01/20/jack-brabham-cooper-t51-climax-pub-corner-longford-tasmania-australia-1960/

Macrow eases Argo into the viaduct at Longford, not sure what day the wet race was. The aluminium body was built, very slowly, by Murray Carter in Moorabbin, a legendary racer of all manner of things, mostly touring cars.

I wrote a feature on the Argo Chev, now owned by my good friend, Pater Brennan, not so long ago. Have a read of it, its an intriguing tale of twists and turns: https://autoaction.com.au/2023/11/05/argo-chev-v8

Etcetera…

Chris Amon tips his ex-works/Scuderia Veloce Ferrari P4/350 Can Am towards the uphill apex of Newry during the 1968 weekend, Chris was the class of the sportscar events. He is about 50-75 metres behind the spot where Argo is in the first shot. Click here for an epic on this car: https://primotipo.com/2015/04/02/ferrari-p4canam-350-0858/

Pedro gives us another look at the Newry poplars and his 2.5-litre BRM P126 V12 during the very soggy South Pacific Trophy race. He nicked second from Frank Gardner’s Brabham BT23D Alfa Romeo in the event’s final stages. The race was won in ballsy fashion by Piers Courage’s McLaren M4A Ford FVA F2 car. See here for the BRM P126: https://primotipo.com/2018/01/25/richard-attwood-brm-p126-longford-1968/ and the 1968 Longford meeting here: https://primotipo.com/2015/10/20/longford-tasman-south-pacific-trophy-4-march-1968-and-piers-courage/

Credits…

Osborne Family Collection via oldracephotos.com, Lin Gigney, Guy Fluke

Tailpiece…

Tony Osborne, Cooper T53 Climax leads Graham Hill’s Scuderia Veloce Brabham BT4 Climax – the race winner – off Long Bridge during the March 2, 1964 South Pacific Trophy weekend. The car following Hill is the ill-fated Tim Mayer in ‘the other’ Bruce McLaren Motor Racing Cooper T70 Climax.

This car, T53 #F2-17-60, the ex-Brabham/Lex Davison provided parts to build Argo. Both Argo and the Cooper exist and are occasionally raced in historic events. Scroll down to chassis F2-17-60 for oldracingcars.com Allen Brown’s summary: https://www.oldracingcars.com/cooper/t53/

The Tim Mayer story is here: https://primotipo.com/2016/11/18/tim-mayer-what-might-have-been/

Finito…