My ignorance of what is right under my nose never ceases to amaze me.

Despite the Trafalgar Holden Museum celebrating its tenth birthday in 2024, I was unaware of its existence until invited along to the official opening of the Neil Joiner Heritage Centre Building on the site of the old Trafalgar Butter factory, 74 Waterloo Road, 125 km north of Melbourne on the Princes Highway.

My invite was as Big Bad Brucie Williams’ bitch, publisher of Auto Action.

250 of the Holden party-faithful attended in a mix of old and new buildings, which house a collection of 150-200 Holdens and memorabilia. The ceremony was performed by the Victorian Minister for Tourism, Sport and Major Events, Steve Dimopoulos.

Dimopolous recognised and applauded the passion of Neil Joiner and his family, he told Auto Action that ‘It’s a magnificent facility, a really important part of Victoria’s industrial and automotive history. We were proud to provide $470,000 to assist in building a museum that will be good for the local economy.’

Local businessman Joiner, who died in 2024, was a dedicated Holden enthusiast who focused on transforming the old butter factory into a Holden museum after his retirement in 2007.

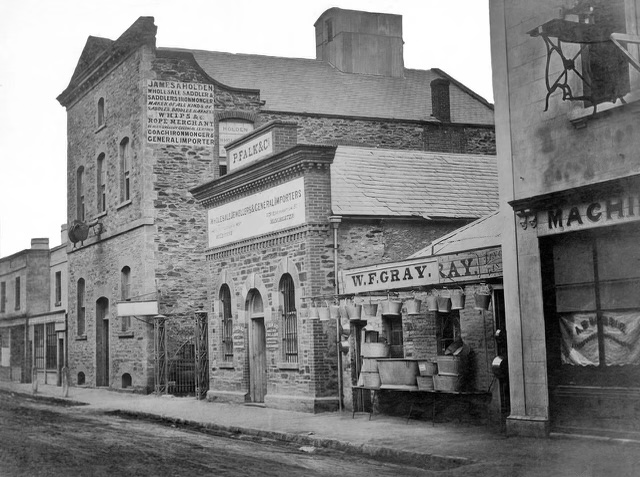

I was aware of Holden’s past as an Adelaide coach builder of horse-drawn buggies long before its automotive growth, but not its far-distant past as a saddlery. This aspect is cleverly explored in an older building recently made over for that purpose.

Joiner’s vision wasn’t just about the cars. It was telling the whole story from the early saddlery and buggy era, armaments made during World War 2, the Frigidaire range of home products and the cars from Holden-bodied Buicks to the last ZB Commodores.

Joiner tipped in his entire collection of cars and memorabilia and Holden came to the party too, with 27 of about 80 cars they have spread throughout Australia.

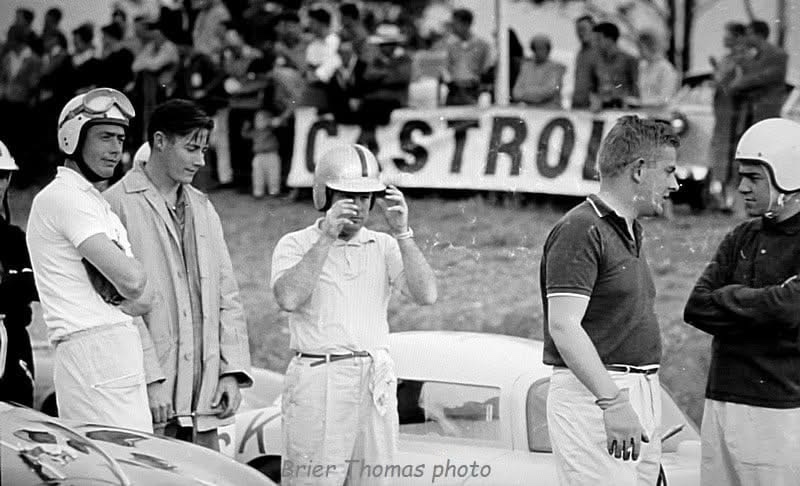

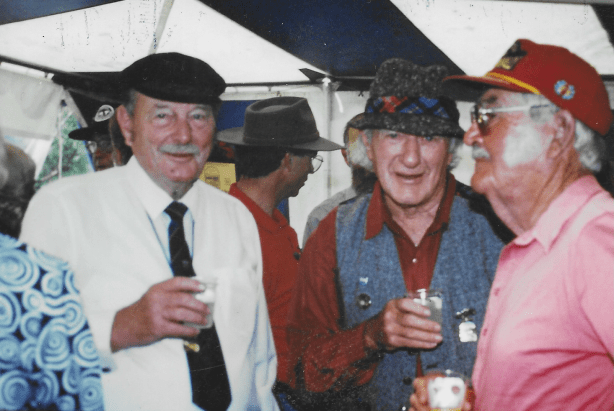

There was a strong presence of Holden identities including Chris Payne, Paul Beranger, Richard Ferlazzo, author/historian Norm Darwin, Erebus’ Chris Payne, Jason Bargwanna, Garry and Barry Rogers, plus an army of enthusiasts.

Rogers owns a farm closeby and has supported the museum with two cars on display, a 2002 Nations Cup Monaro CV8 427 (foreground) and the ZB Commodore Supercar (at rear) raced by Tyler Everingham and Jayden Ojeda to 19th place in the 2019 Bathurst 1000. The car looks magic in as-finished-Bathurst condition.

Holden Monaro CV8 2002 Nations Cup Specifications (yellow car)

GRM-built chassis with integrated chrome-moly roll cage

7-litre (427 cubic inch) all-alloy Gen III V8 engine built by GRM a specific racing version of the Chevrolet LS engine with capacity increased from 5.7-litres. Holinger 6-speed sequential gearbox, AP triple-plate 7.25″ carbon clutch

Fully independent rear suspension developed by Harrop Engineering, Ohlins shock absorbers. AP 6 piston mono block front calipers / 4 piston mono block rear calipers. Front rotor – 375 x 35mm, rear – 343 x 35mm

18″ x 13″ OZ Racing rear wheels / 18″ x 11″ OZ Racing front wheels-centre-locking nuts, Dunlop GT racing tyres (FIA specs)

120-litre FIA-approved racing fuel cell with Siamese dry-break refuelling system. GRM-designed and developed carbon-fibre / Kevlar composite aero package. Motel onboard engine and dash management system. 4 onboard air jacks

The museum is a must-visit for all car nuts, not just the rusted-on Holden diehards. I’m a Ford man, I’ve never owned a Holden, but Dad had plenty of them as company cars – remember that pre-FBT perk?! – So I’ve plenty of experience driving them as well as having plenty of firsts inside Holdens! Like most of us over 15, I suspect.

What did he have now I think of it? EH Wagon three-on-the-tree and then autos: HD, HR and HK wagons, then HG and HQ Premier sedans before switching to the dark side with an XB Fairmont and Fords thereafter.

What follows is a random potpourri of shots of cars and exhibits that caught my eye. The verbiage is the Museum’s not mine. Do go up and have a look, its really great.

The first Holden 48-215 to roll off the Woodville production line on November 1, 1948, was driven by Holden’s MD, Harold Battle, with engineer Russ Begg alongside. See here: https://primotipo.com/2018/12/06/general-motors-holden-formative/

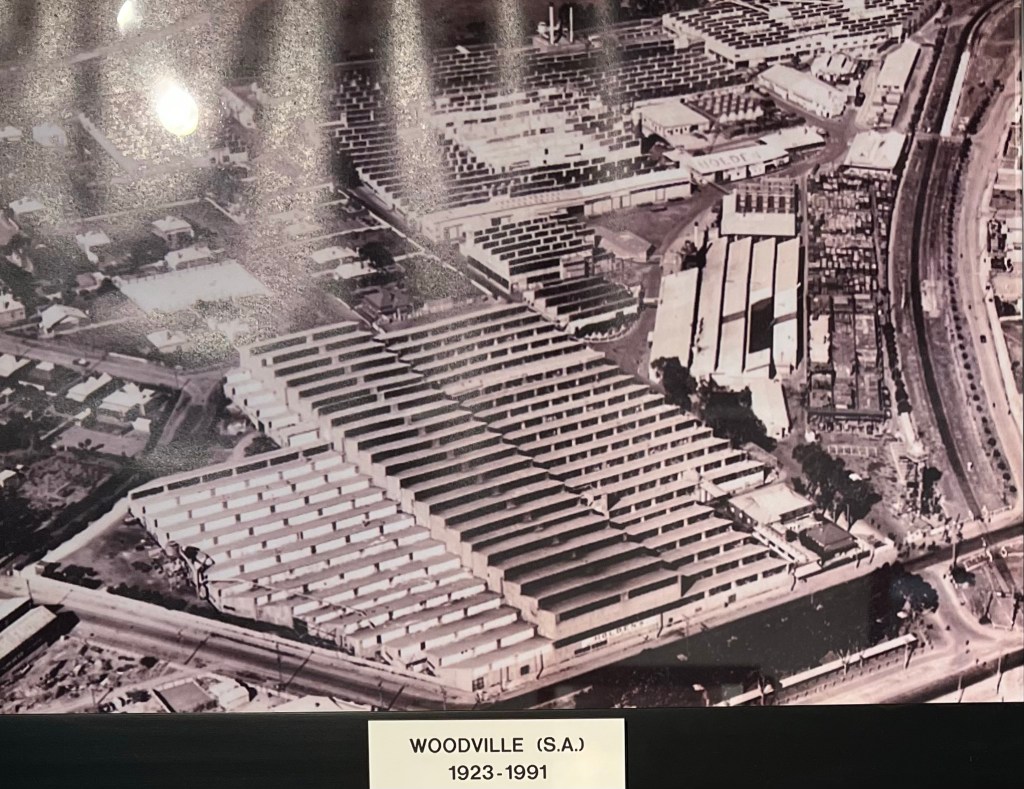

Woodville Plant, South Australia…

‘Throughout Holden’s 158-year history, SA has been the source of horse drawn coach and automotive body manufacturing engineering development and production for the company.

First automotive bodies were designed and manufactured in 1917, meaning Holden was in the automotive manufacturing business for 100 years by the 2017 closedown of manufacturing.

Established in 1919, known as Holden’s Motor Body Builders Ltd. (HMBB) manufactured bodies at its King William St Adelaide factory and at Woodville from 1925 where it employed 5,500 people.

HMBB made bodies for 40 different brands of cars. Over half a million bodies were made before the Holden 48-215 was launched. Exporting of bodies commenced in 1939.

Within the first few years of operation Woodville became one of the biggest body manufacturers in the world as well as being the sole supplier of car bodies for General Motors in Australia. GMH was formed by the merging of HMBB with the assembly plants previously operated by GM Australia.

Forced by Australia’s isolation during WW2, the need for innovation, improvisation and invention was paramount in all Holden plants. Woodville became the largest producer of war related equipment and supplies within GMH.

After the war, major advances in body manufacturing engineering, sheet-metal press tooling, body assembly jigs and fixture design together with press and body assembly production systems centred around Woodville.’

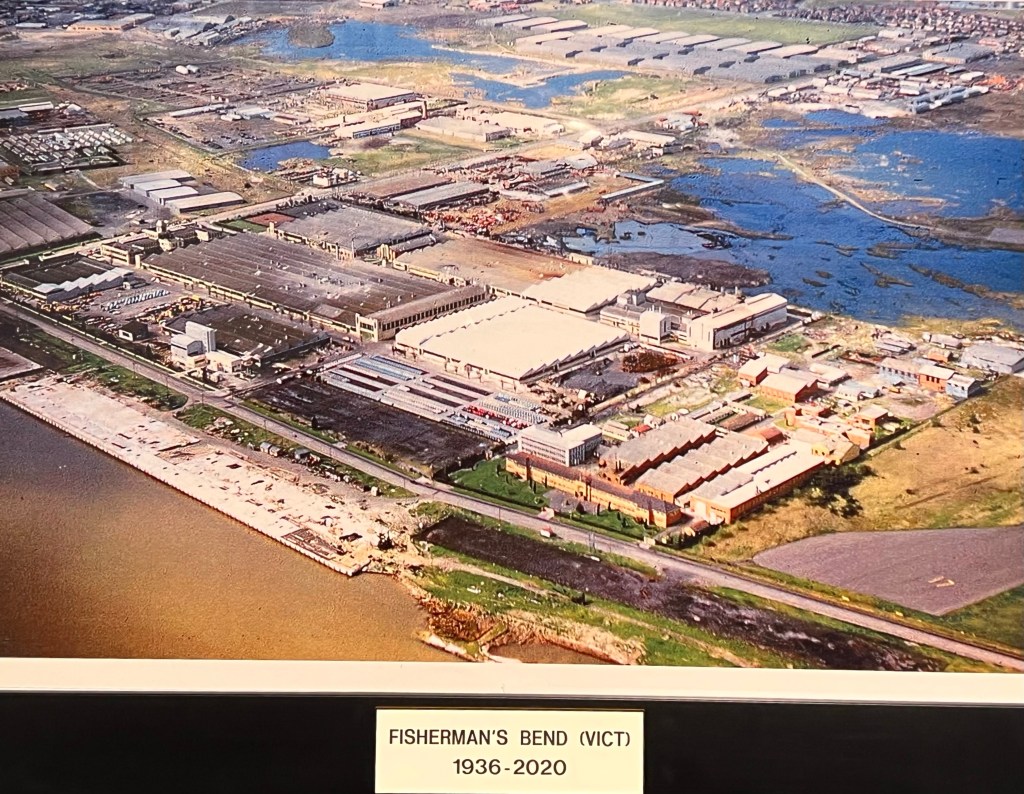

Fishermans Bend, Melbourne…

‘Head office was transferred from SA to Fishermen’s Bend, Melbourne. Opened in 1936, Fishermans Bend (correct spelling) became Holden’s headquarters, as well as its product design and product engineering centre.

During WW2 it produced a vast array of war equipment, including the development and production of many types of trucks. Critical to Holden’s future was the introduction of a world class foundry duringWW2 to produce engine blocks and heads.’

‘The plant assembled the first Holden car, the 48-215, based on fully trimmed bodies being supplied from Woodville, South Australia, and most mechanical components being made in Fishermans Bend plants. It produced the vast majority of the mechanical components in the car including the engine, transmission rear axle and suspension components. This was at a time when the Australian automotive supplier industry in Australia was not well developed, so Holden manufactured a lot more of the car internally.’

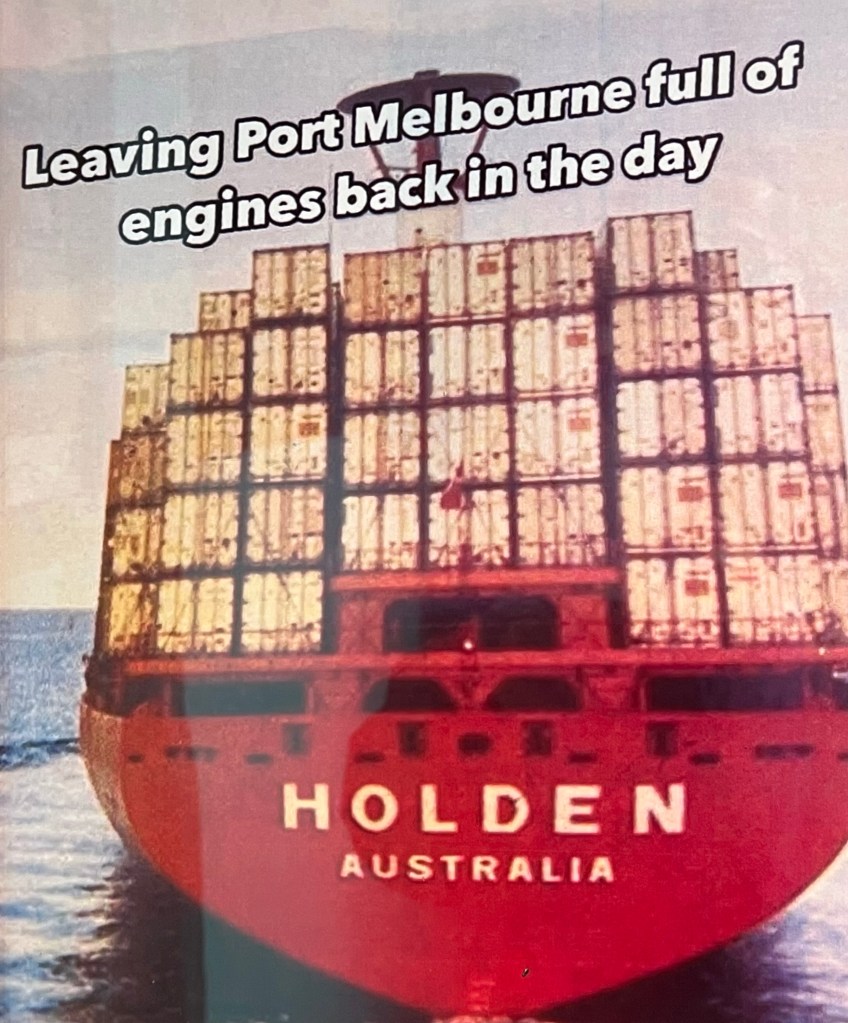

‘In 1956 vehicle assembly in Victoria was relocated to a new Dandenong plant. The Fishermans Bend plant was reconfigured to concentrate mostly on engine manufacture for domestic and for 4-cylinder export territories. It became Australia’s largest exporter of elaborately transformed goods. The famous 6 cylinder in line and V8 Holden engines were produced here.’

‘Fishermans Bend went on to produce a peak of 960 engines per day up until November 29, 2016, when it was closed after 76 years of engine manufacturing.’

Export…

‘Holden had a significant program running for many decades beginning with the FJ exports to New Zealand in 1954.

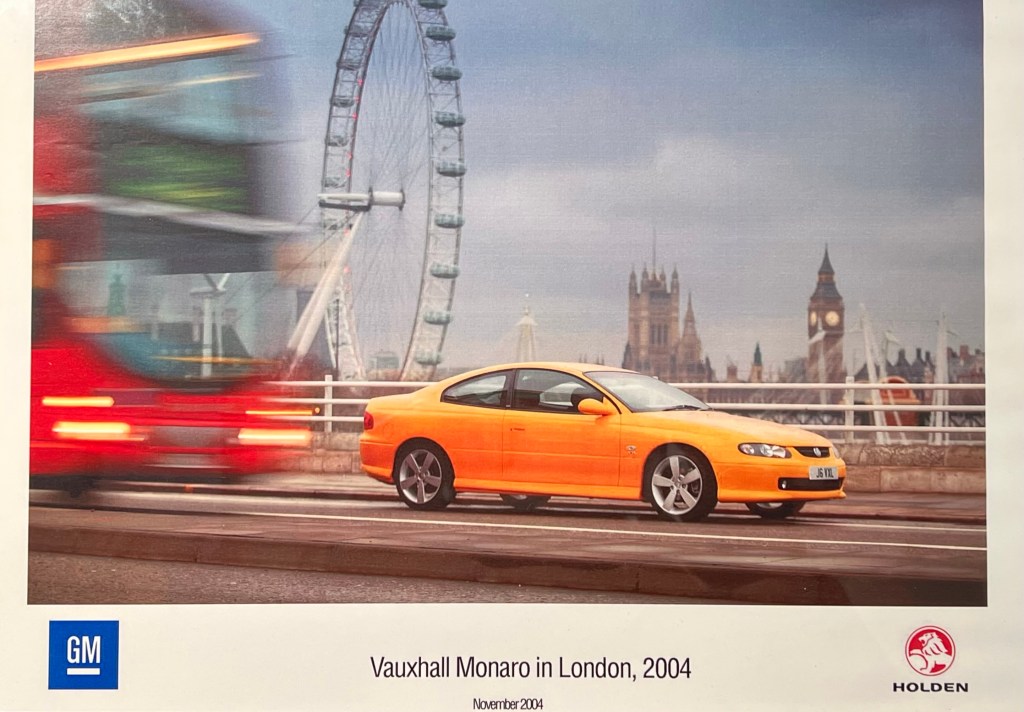

In later years exports were most significant in the Middle East and America with both the commodore and Statesman nameplates being altered to both Chevrolet and Pontiac, but the vehicles were Holden.

Over the years Holden exported completely built-up cars (CBU’s) cars in parts and assemblies to be assembled at their destination (CKD packs) and of course engines and other componentry. These programs added billions of dollars of income to the Australian economy and validated Holden as a producer of world class vehicles, automotive engines and componentry.

As well, Holden exported its incredible expertise and knowledge in the design and development of cars for its parent company in the USA, General Motors.’

The Holden Emblem : The Lion…

‘As an emblem, the Holden Lion relates to the time when coach builders engraved their company name or trademark on the door sill, or on a plate fixed to the instrument panel.

In the early 1920s Holden Motor Body Builders used a large brass plate embossed with a winged figure representing industry against a background of factory buildings. In 1926 the company decided to downsize the brass plate and emulate the practice of Fisher Body in the USA, which attached a neat replica of its coach trademark to the lower part of the cowl. Because the existing emblem was too detailed to be embossed on a small plate, a new design was commissioned to be based on the Egyptian-style ‘Wembley Lion’, symbol of London’s 1924-25 British Empire Exhibition. Fashion themes of the time from clothing to furniture, films and songs all were influenced by Egyptian antiquity.

According to fable, the principle of the wheel was suggested to primitive man when observing a lion rolling a stone. Thus inspired the pre-eminent Australian sculptor of the day George Rayner Hoff, to create the ‘lion and stone’ sculpture. This was replicated in a pressed metal plate that was fixed to all bodies built by Holden’s Motor Body Builders from 1928.

More than 75 years later the evolution of the lion and stone symbol can be traced through series of badges proudly worn by a cavalcade of cars, some recognised by early GM model enthusiasts but most dear to the hearts of generations of Australians since 1948 advent of the 48-215 or FX Holden.

The chrome-winged surround on the FX/FJ grille badge was Cadillac inspired.

The classic Egyptian lion design gave way in 1972 to a more modern interpretation of the symbol, which in turn was replaced in 1994 by the powerful Holden brand we are familiar with today.’

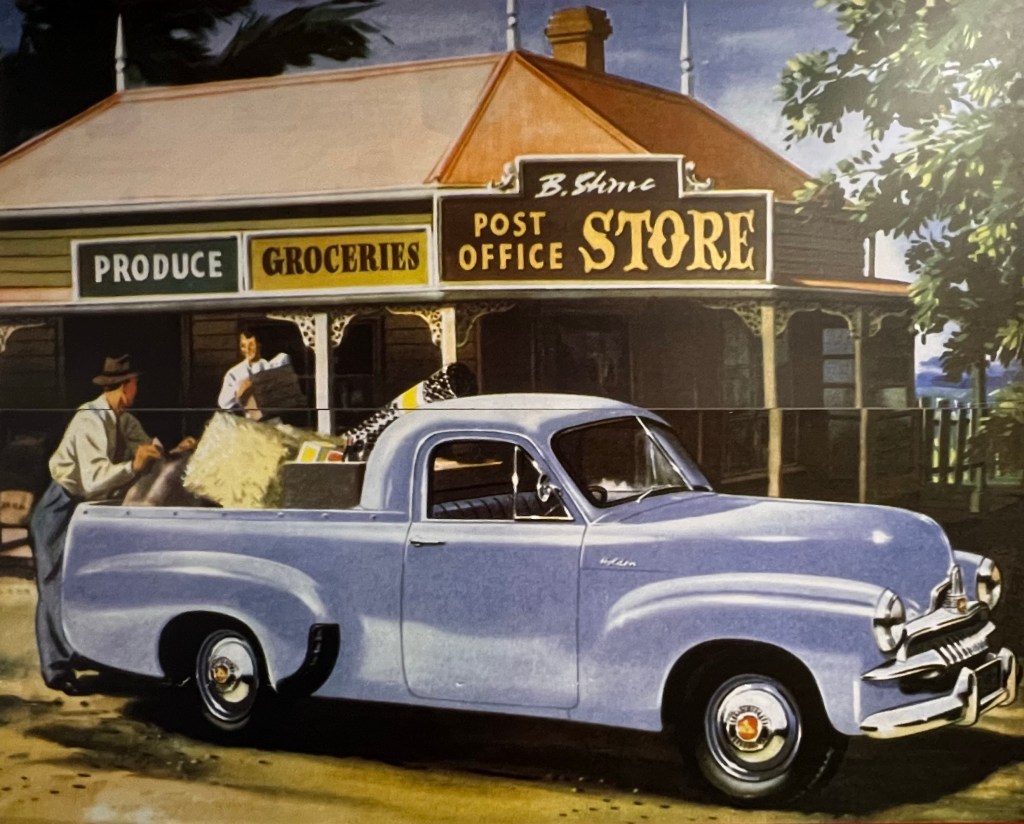

Holden 132 CID Grey motor…

Powered cars such as the FJ Ute above.

‘The introduction of the first Holden car in 1948, the 48/215, saw the first mass produced car engine in Australia.

Designed in 1938 by GM for Project 195-Y15, it was only used in the Holden car and all production Holden’s were fitted with engines made in a purpose built facility at Fisherman’s Bend, Melbourne.

Though small in capacity, the use of six cylinders ensured a smooth, efficient engine with good torque, giving the lightweight 48/215 more than adequate performance.

Dubbed the Grey motor on account of their paint, about 650,000 of these 132 motors were made from 1948 to 1960 and many were sold for use as stationary engines to drive generators, pumps and the like.

Type 6 cylinder, 7 port head. Capacity 132.5 cid, 2171cc. Inlet valve size 1.28, 32.5 mm. Power 60bhp, 44.5kw @ 3800rpm.’

The search for Power…

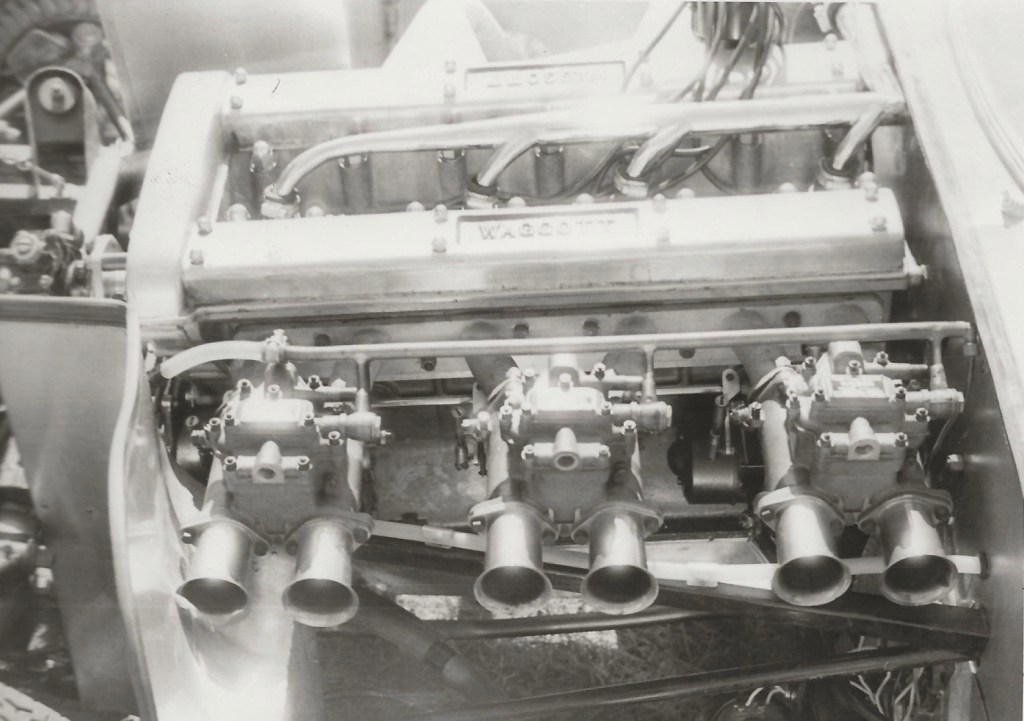

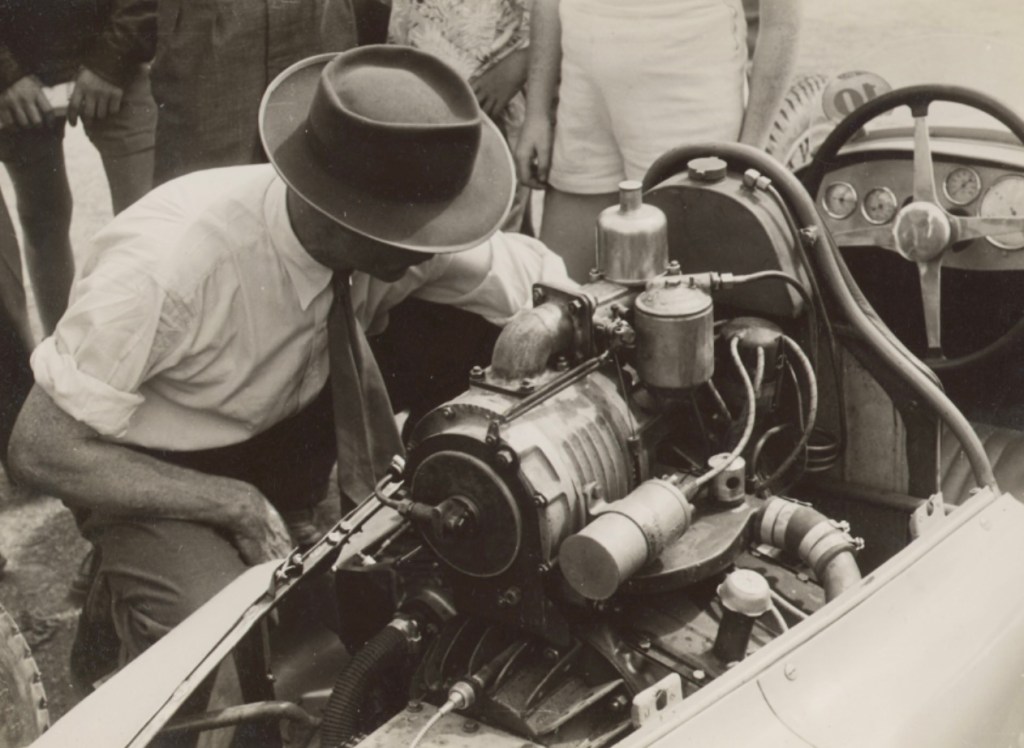

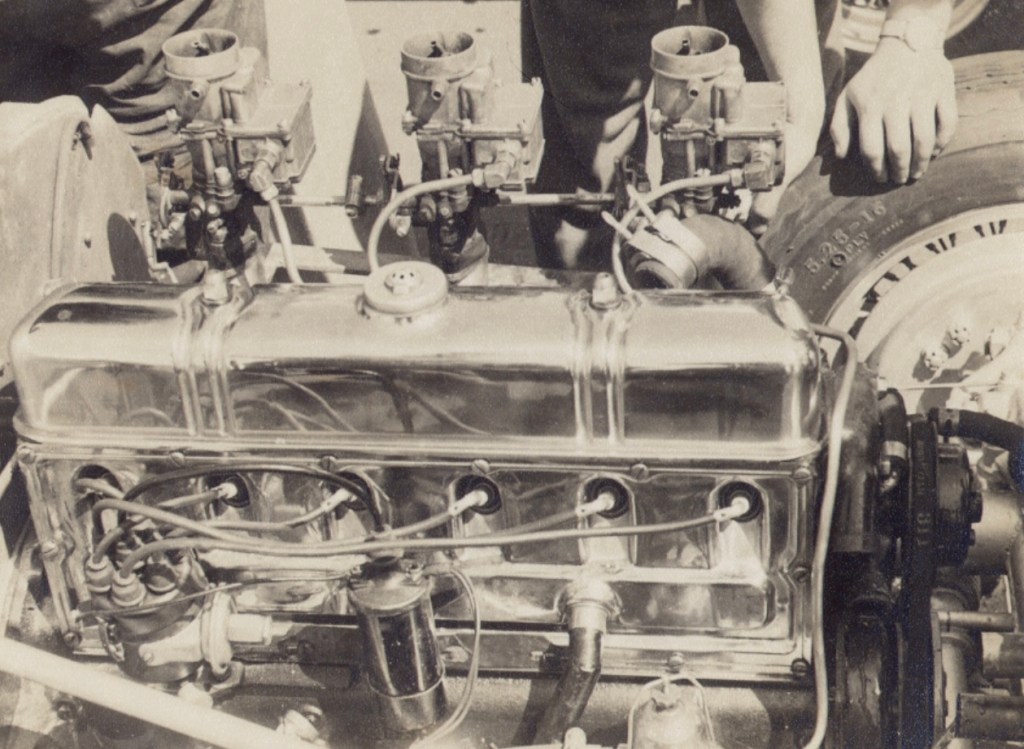

‘This display is the 3-litre model 186 engine which was produced from 1966 to 1970 and is fitted with a ‘Cyclone cylinder head’ designed and developed by Phil Irving and Bob Chamberlain.

The head is one of the six that were made of cast steel. Later another 25 were made of alloy before the project ended. Development started when the Holden engine driving a new boat drive, that Bob Chamberlain designed, did not have enough power pull the skiers fast enough.

Phil Irving had previously designed a cylinder head that was thought would give the extra power required. So together they decided to develop it in their Port Melbourne workshop where the first two were cast and machined.

The head is a ‘Heron type’ which has the combustion chamber in the piston and not in the cylinder head. The head has the Inlet ports at 30degrees and the hydraulic valve lifters are replaced with solid lifters. It is fitted with an inlet manifold similar to the E-Type Jaguar and has three SU carburettors. Two other manifolds were tried out with a Stromberg and another with a 4-barrel Holley carburettor.

All three when tested on a dynamometer gave similar results of around 150bhp as against 90 bhp in the stock standard 186 engine. Other than that the rest of the engine is standard.

While the engine performed well in the stock car mode it was found to overheat in the boat due to the constant high revs required to keep the boat planing, whereas the changes of speed allowed some cooling in the car.’

Holden Bodyworks…

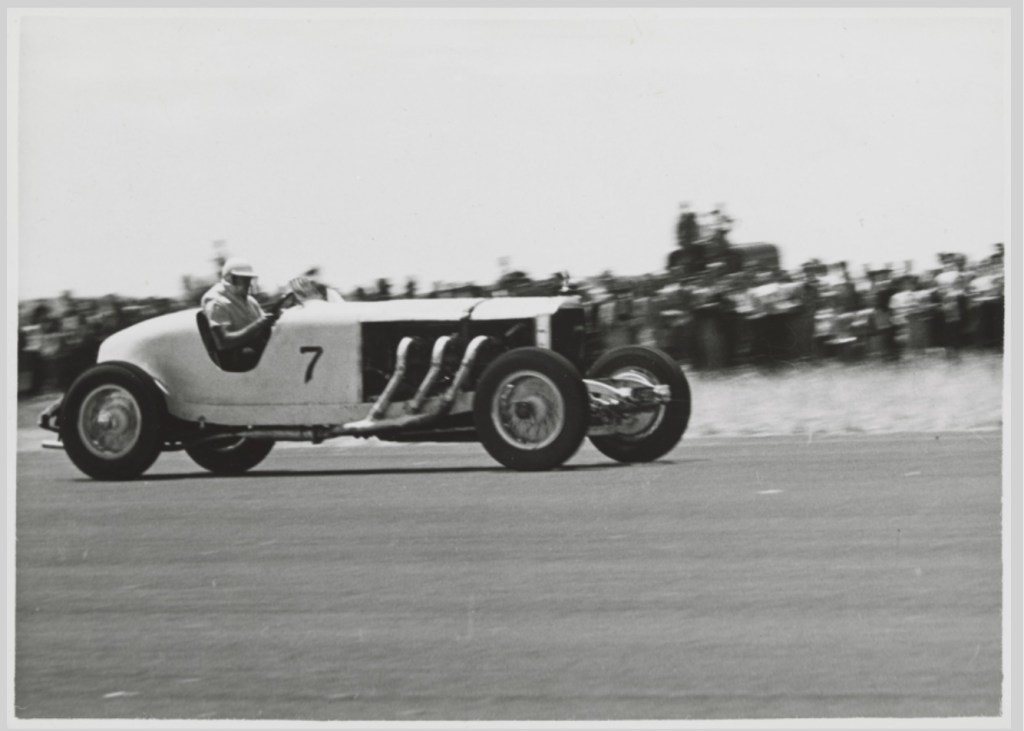

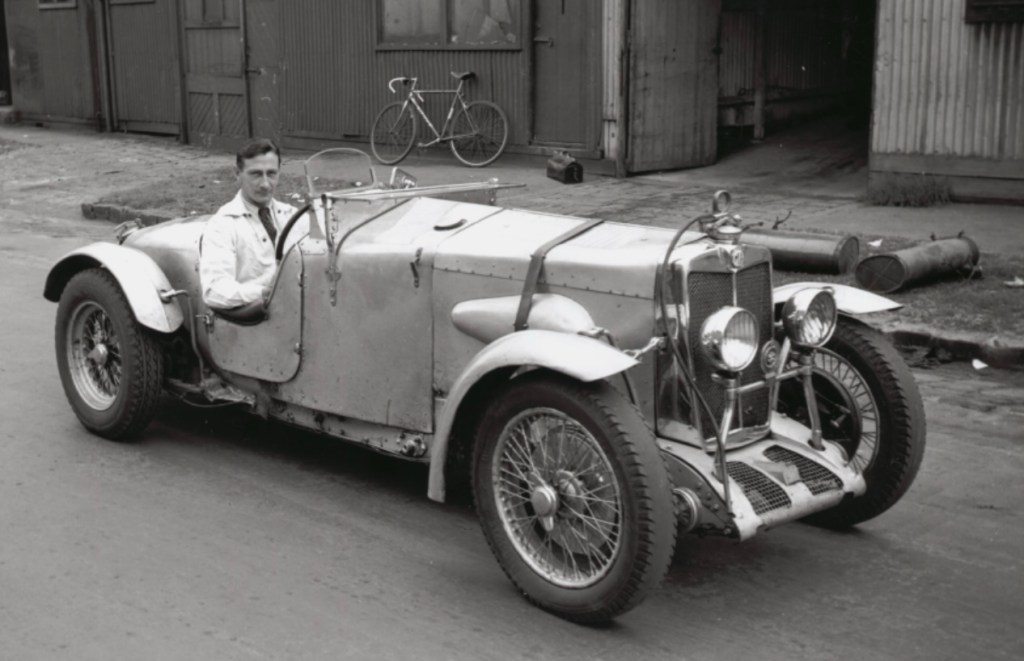

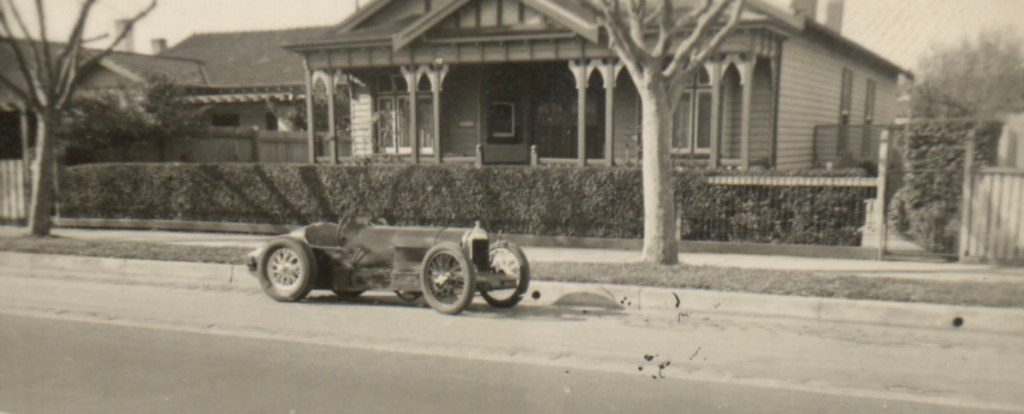

‘If cars could talk, few would have as many stories to tell as this stunning 1928 Buick Speedster.

Built by Holden Bodyworks in 1928, the car was shipped to England for performance improvements and to compete in the Brookland Time Trials. Calculations confirm the car would have been capable of 140mph at just over 5000rpm. This is far in excess of top speeds that were being achieved at that time for any production type car.

The car was noticed in the Brooklands track car park by two Vickers test pilots and they were encouraged to take the car for a spin around the track for a bit of fun. The recorded oncaged to attain an unofficial top speed of 138mph without crashing. This is 20mph faster than anything But things turned sour for the record-setter, with police closing down the track after several high-speed crashes had resulted in death.

Unable to continue racing, the Buick returned to Australia and was sold to a private buyer in Mildura who saw porentia in its speed.

Painted matte black, with its headlights removed and holes cut into its body to accommodate barreis, the car was used to run moonshine (illegal alcohol) across the Victoria-NSW border between Mildura and Echuca. Travelling only at night using moonlight for navigation, the Buick became known to locals as the mocnight speedse The dutlaw car evaded police until its eventual capture in 1964.

Seizure under the new proceeds of crime laws saw its demise, with the car crushed and puched into a creek, a mere lay forgotten for 20 years forgotten.’

Is this for real?? Sounds like a touch of the Donald Trumps to me?

Five years before I finally made it to a race meeting in 1972 the Holden Precision Driving Team blew my tiny mind at the Royal Melbourne Show.

‘We all saw them’ perform around Australia wherever we lived. Monaro GTS sedans above, and coupes below, venues folks?

This one gave me a chuckle too.

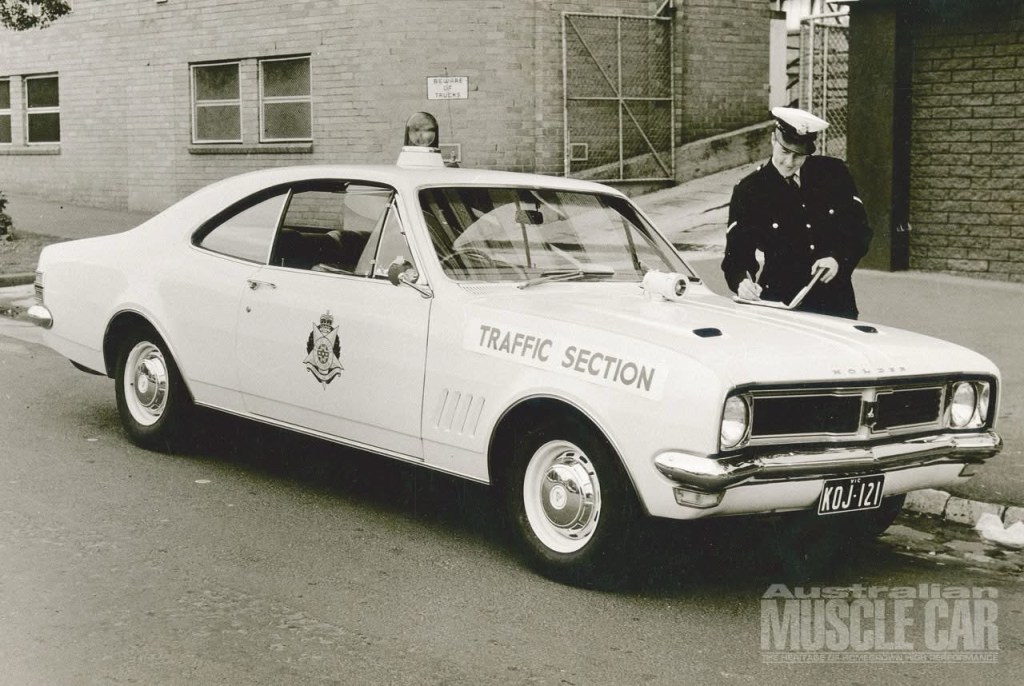

Blanchards Holden were on one of Melbourne’s busiest intersections, the corner of Springvale and Dandenong Roads, Springvale, only a drop-kick from Sandown.

It’s a mega corner of about six bits of road these days, but that roundabout in the late-1950s – the line-up of FCs makes it 1958-60’ish – looks pretty lame…

Etcetera…

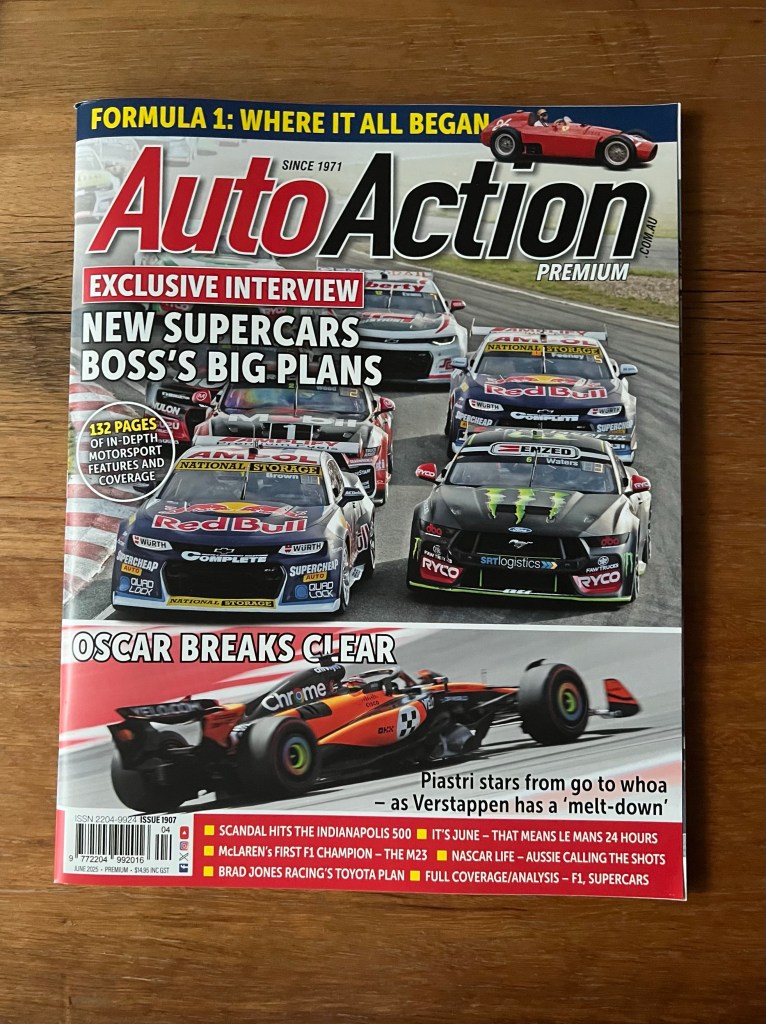

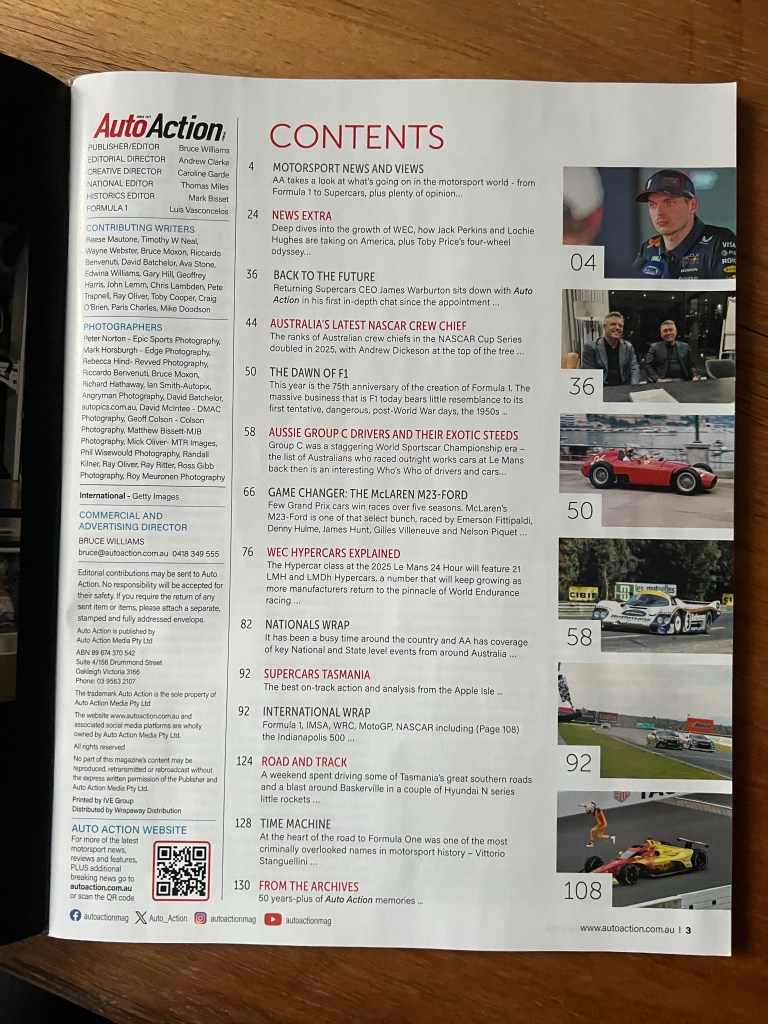

Don’t miss the latest, June Auto Action, on-sale for only the next few days, see below for the contents. The July 132-page monthly, issue #1908, will be in store this Thursday/Friday.

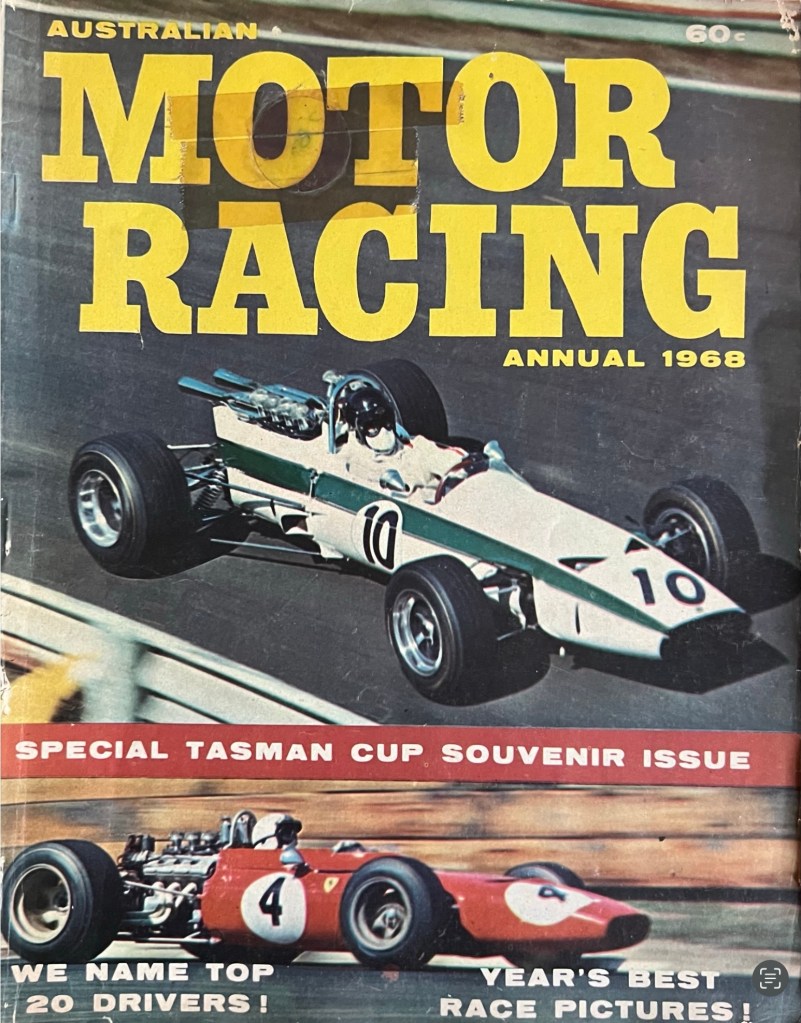

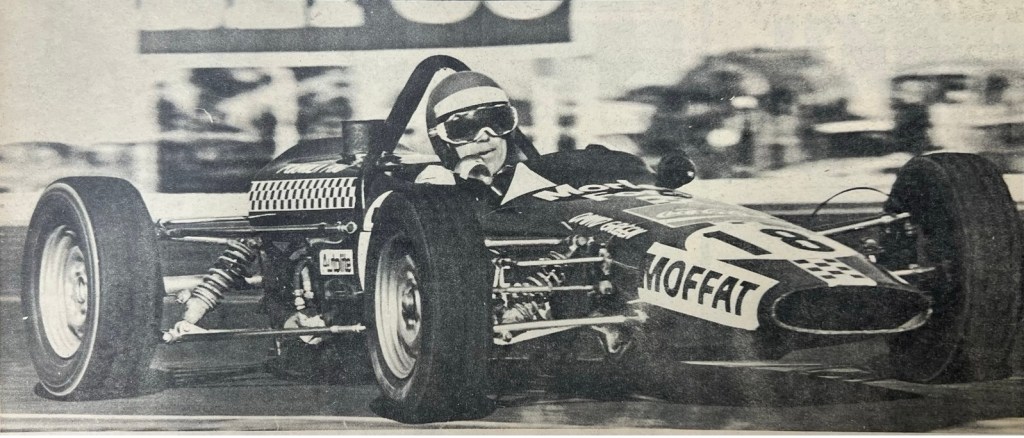

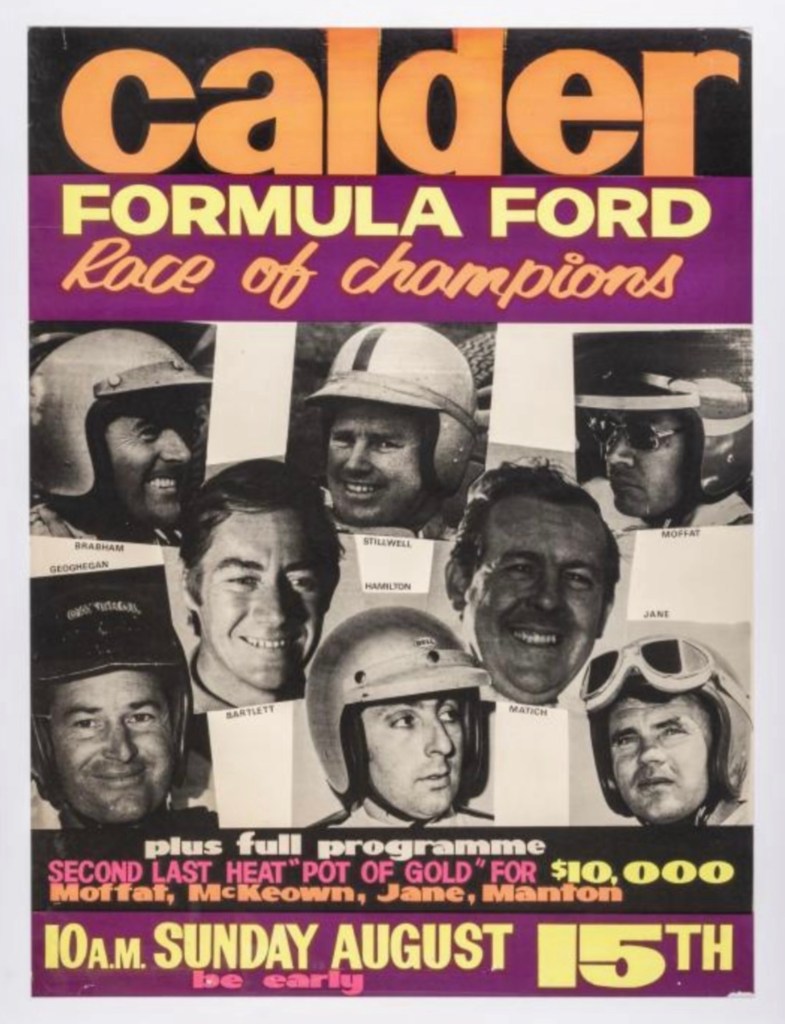

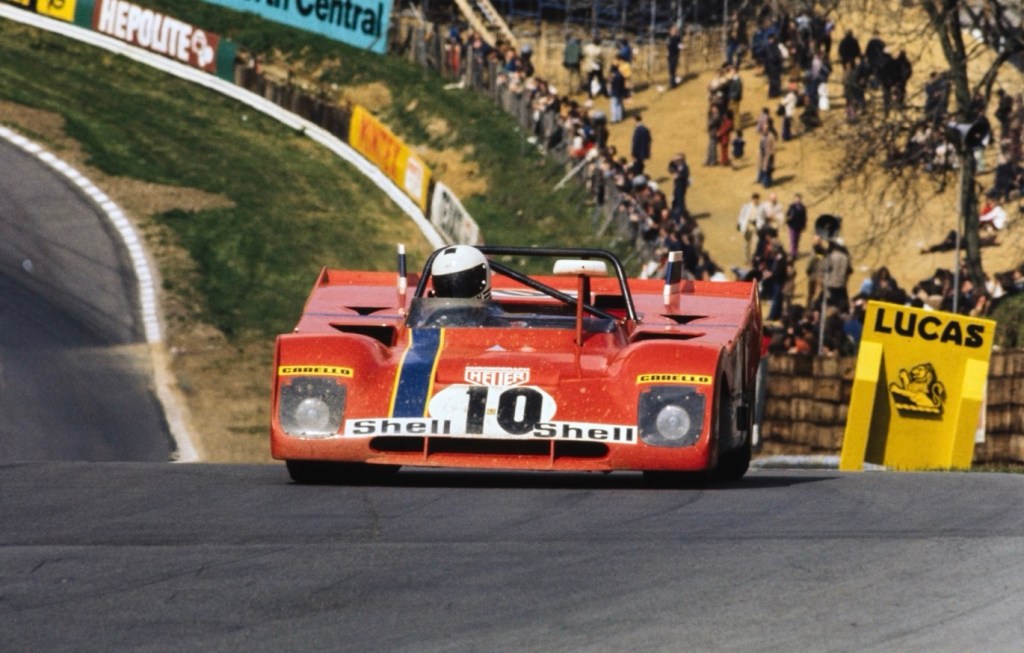

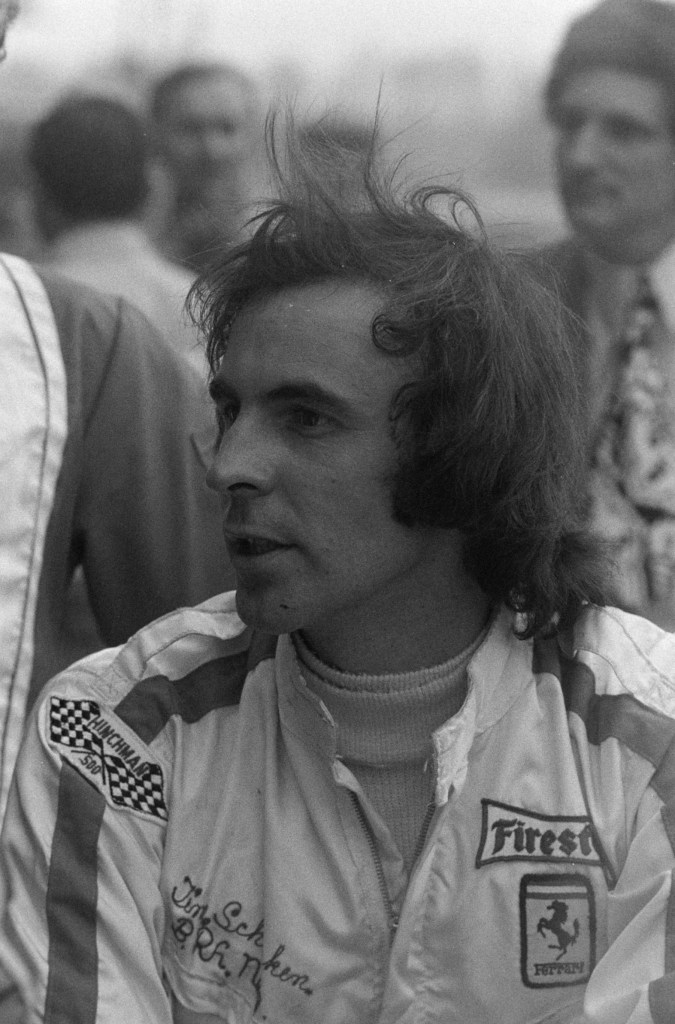

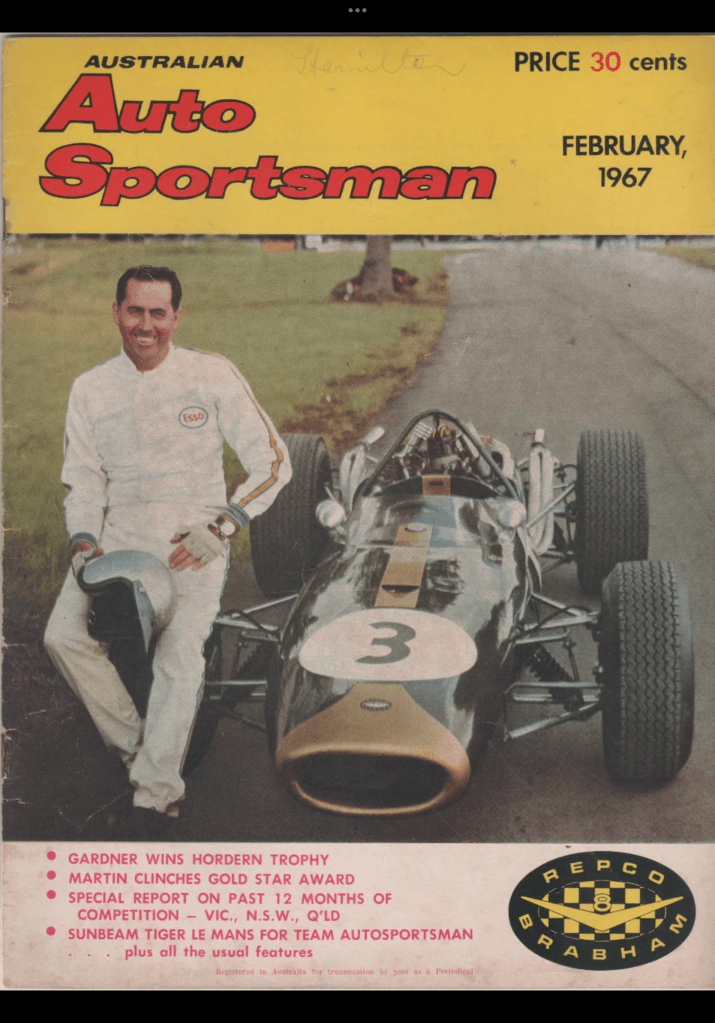

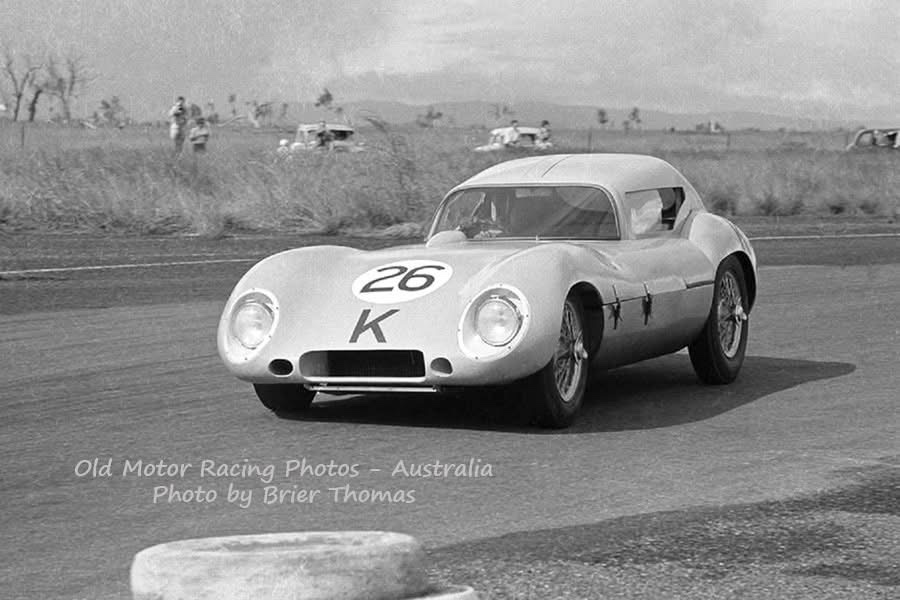

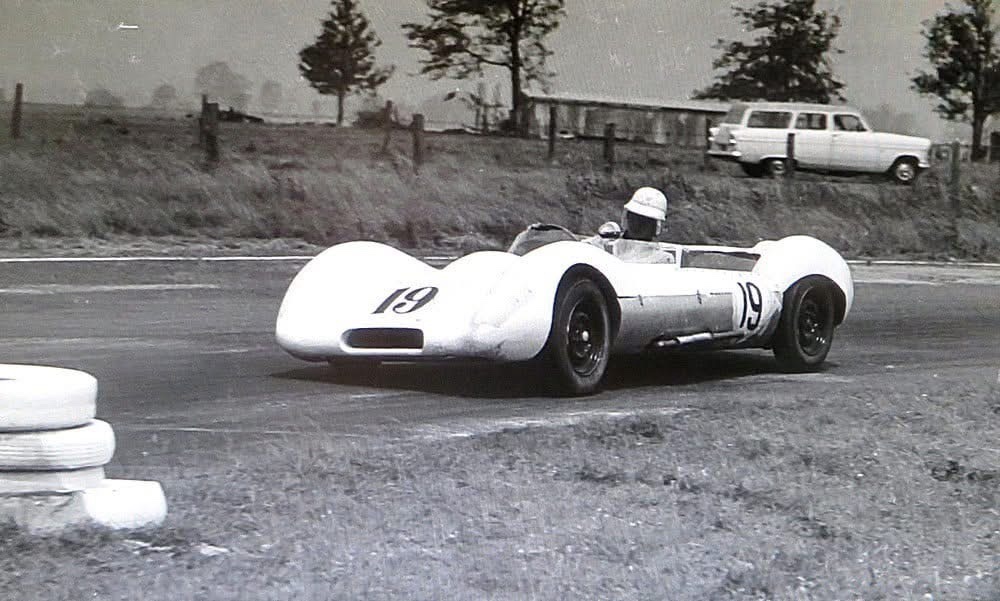

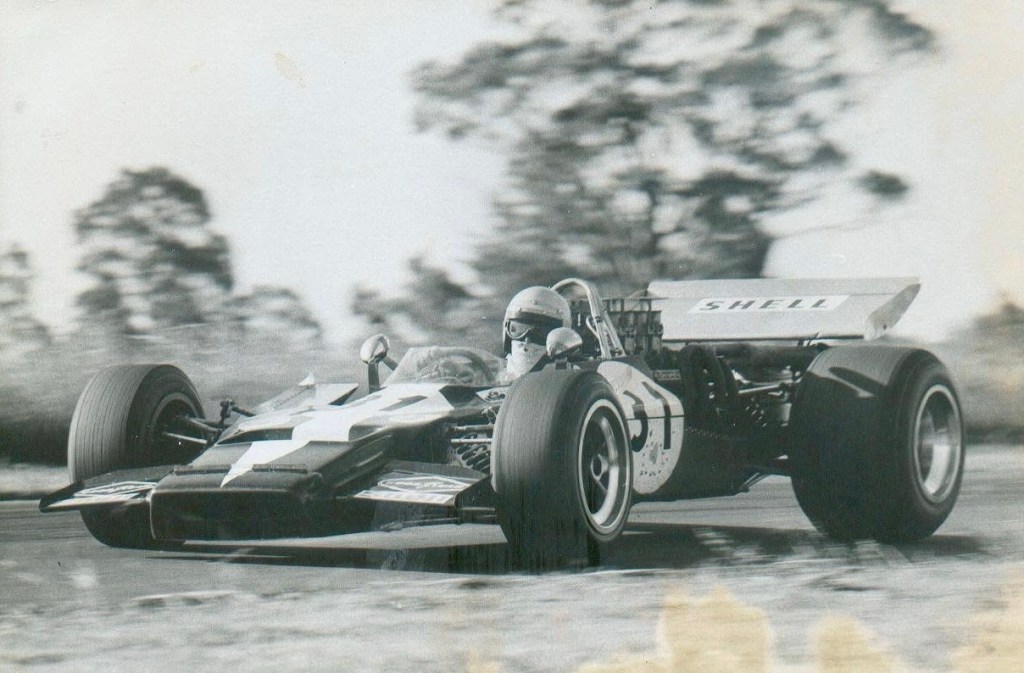

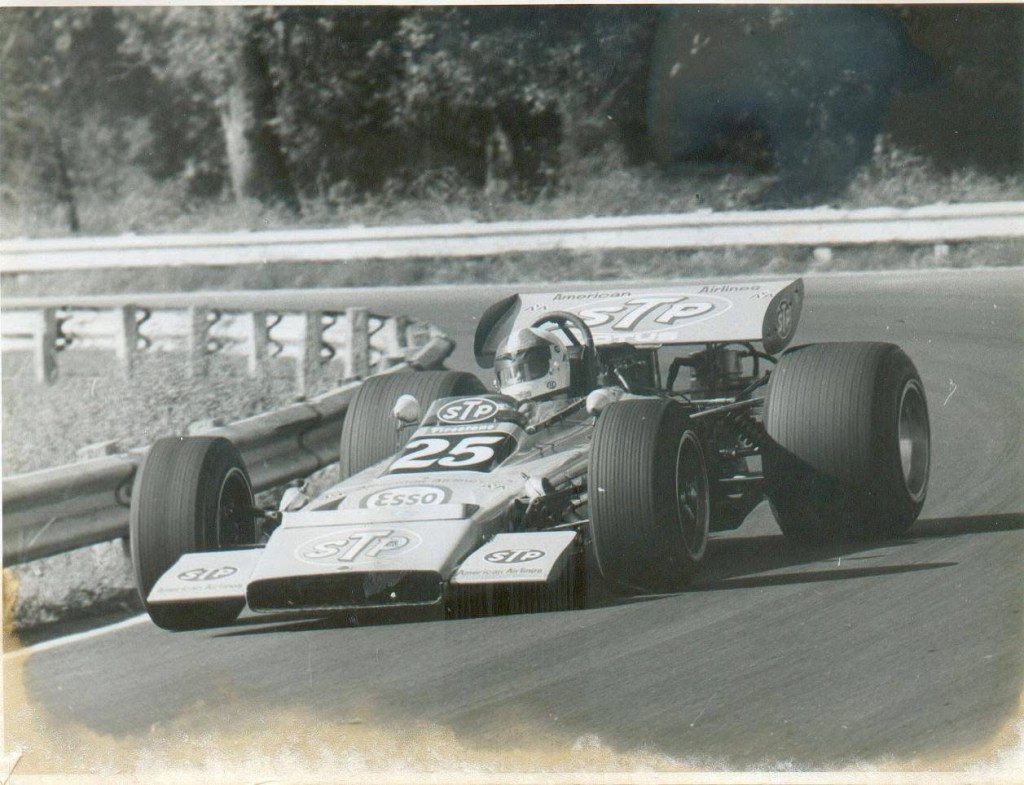

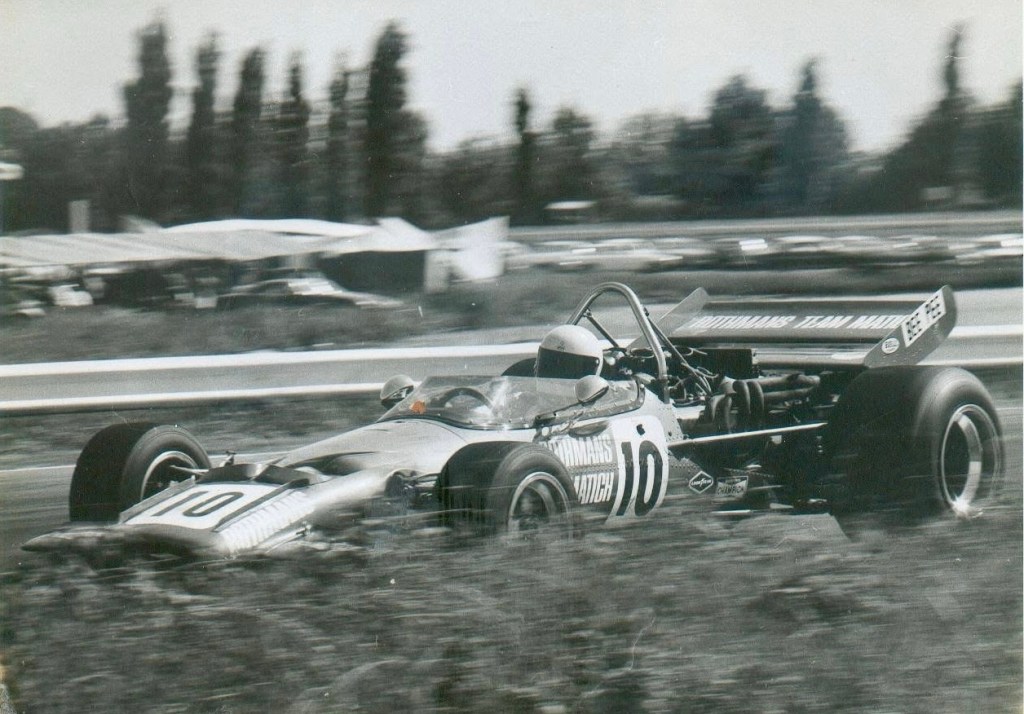

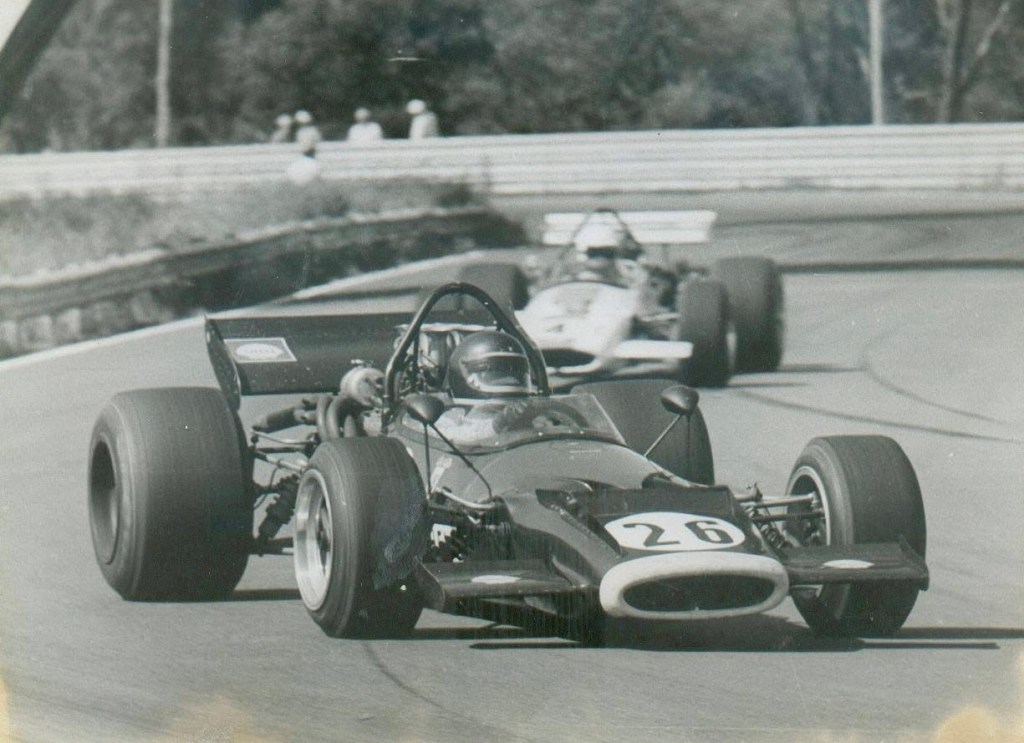

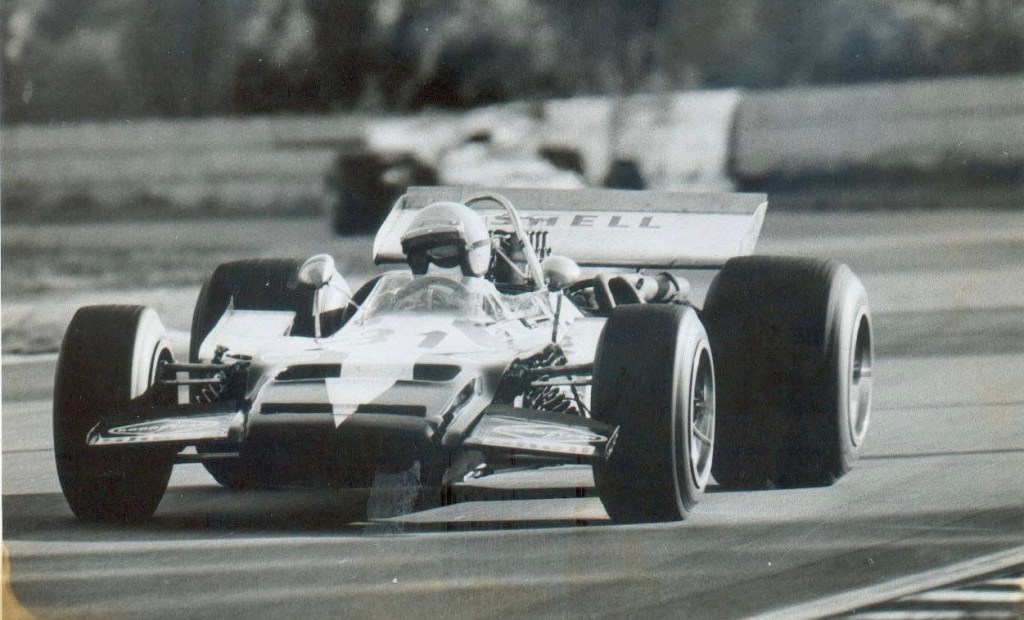

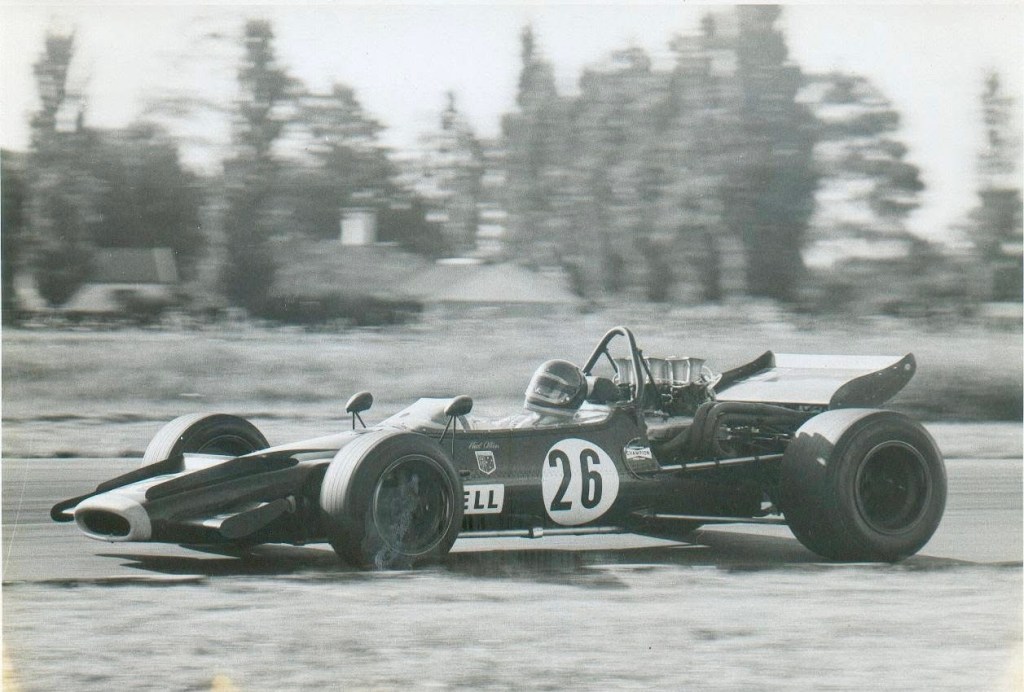

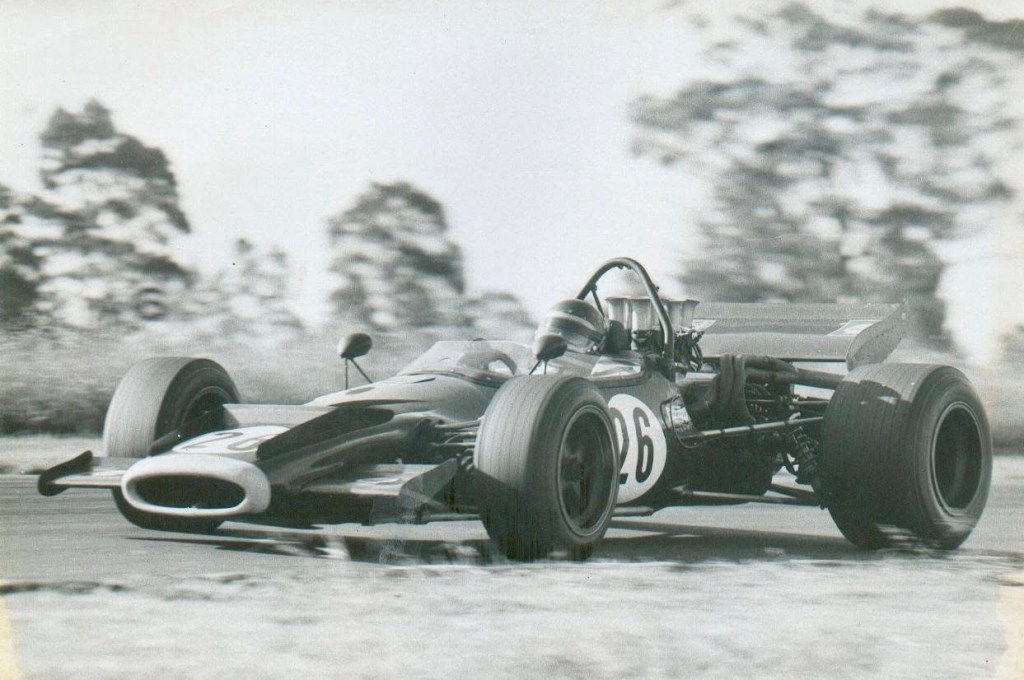

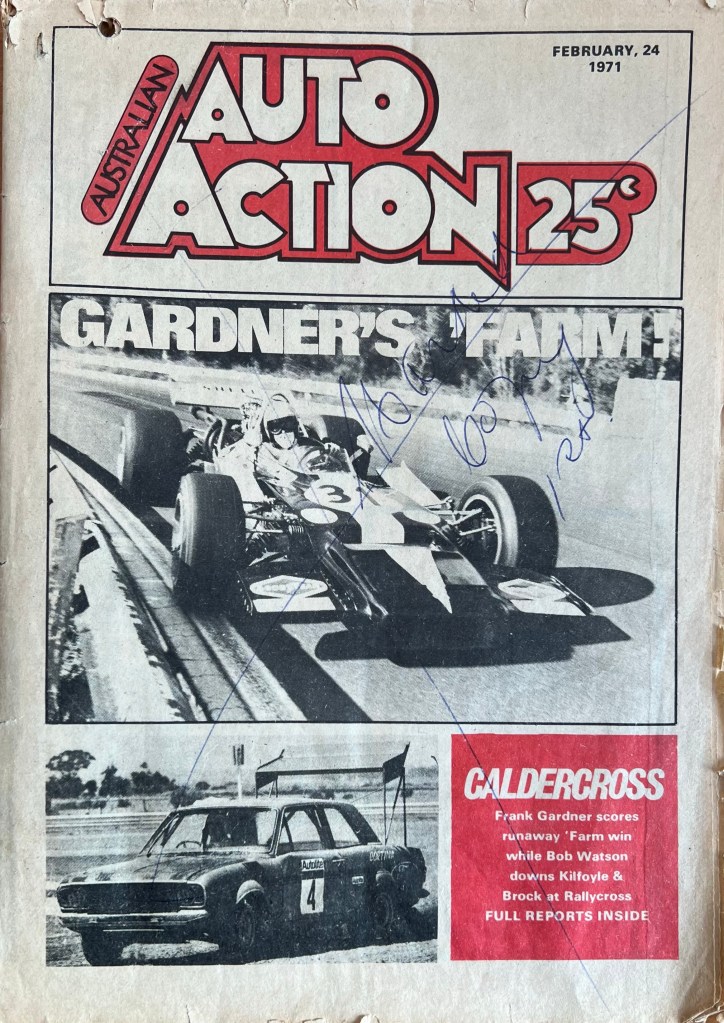

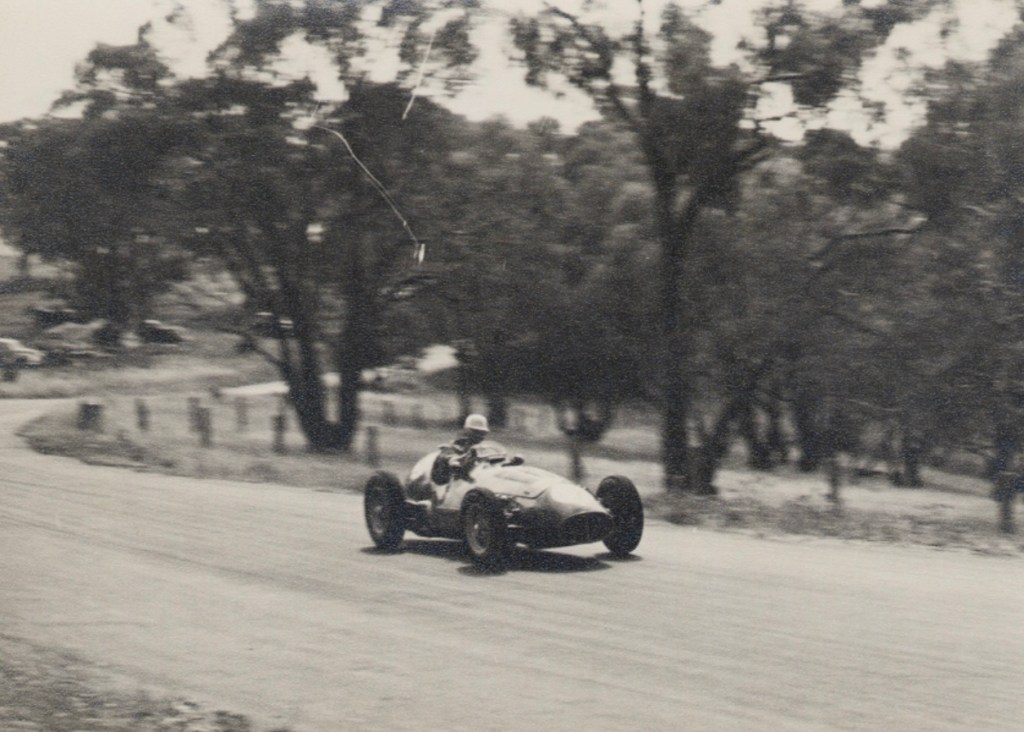

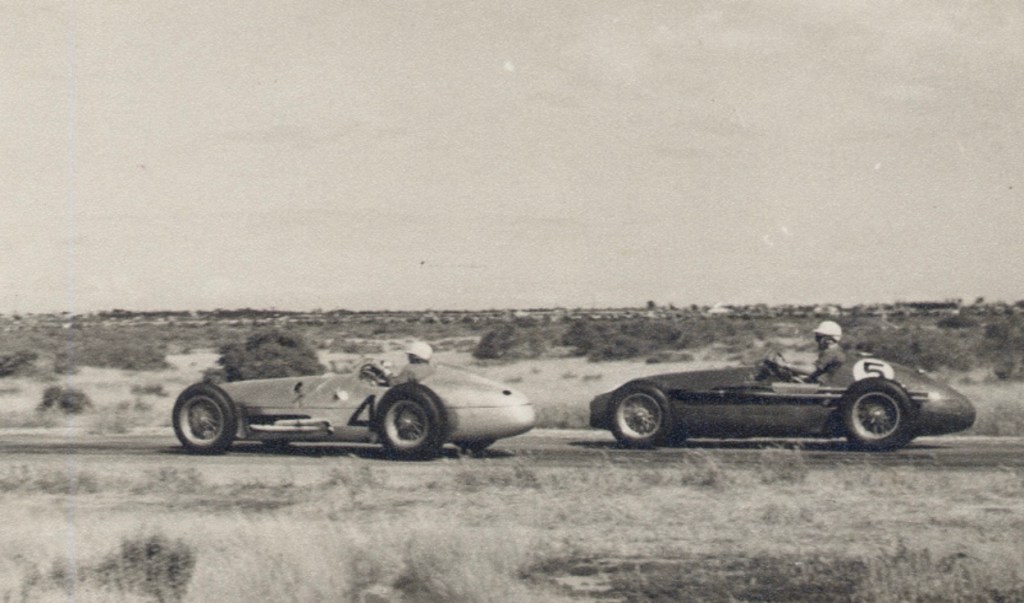

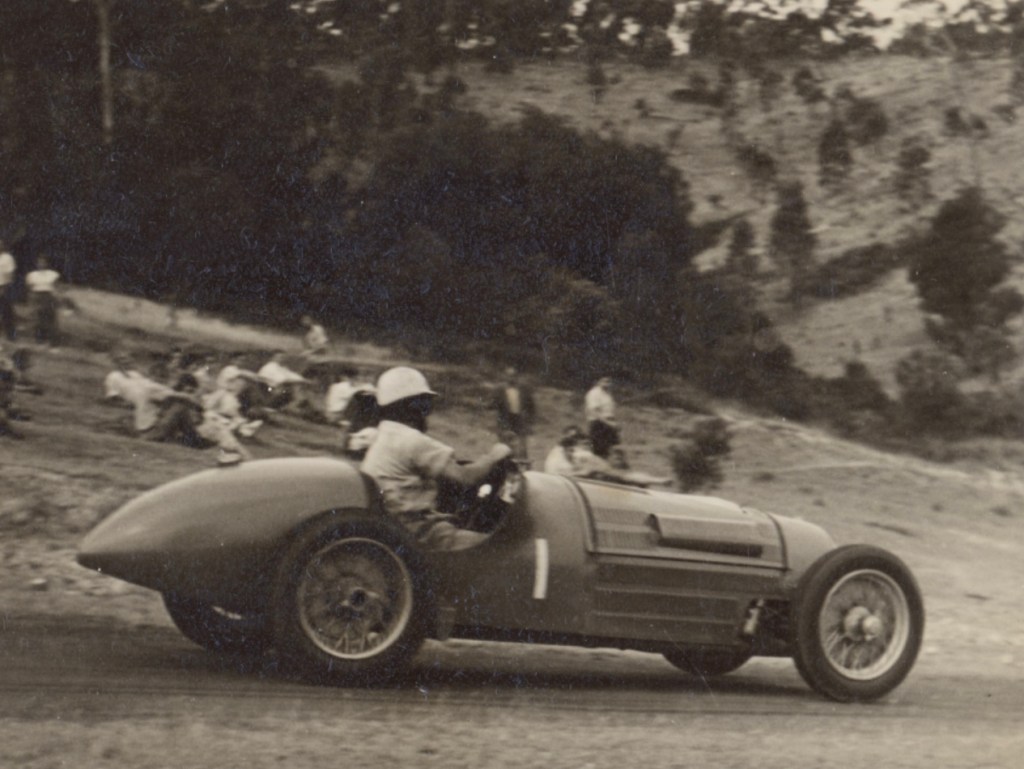

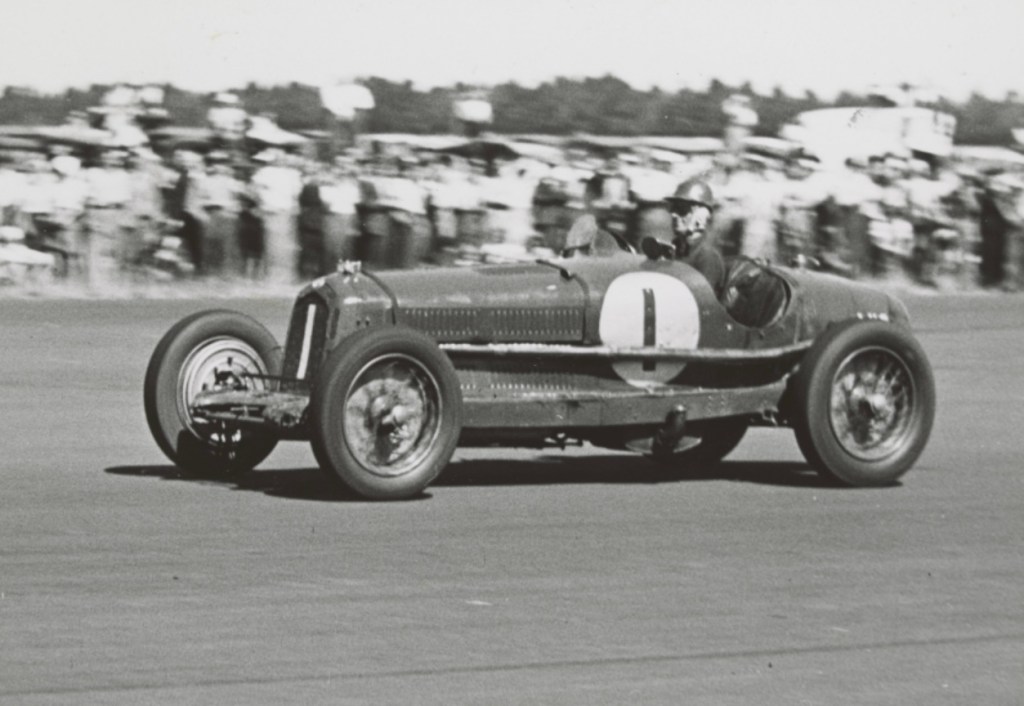

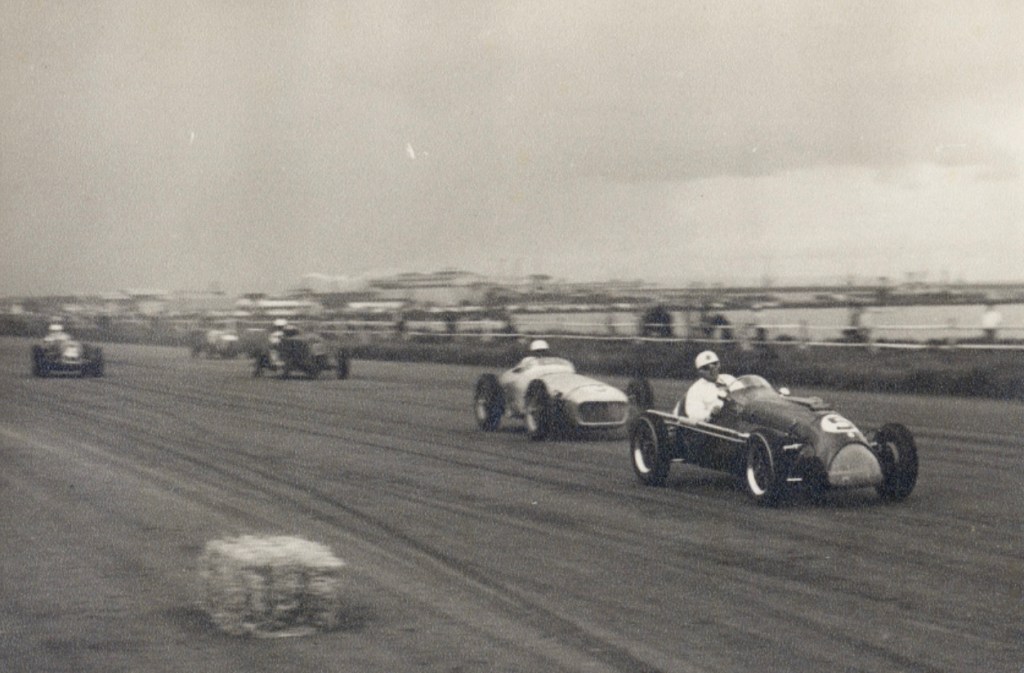

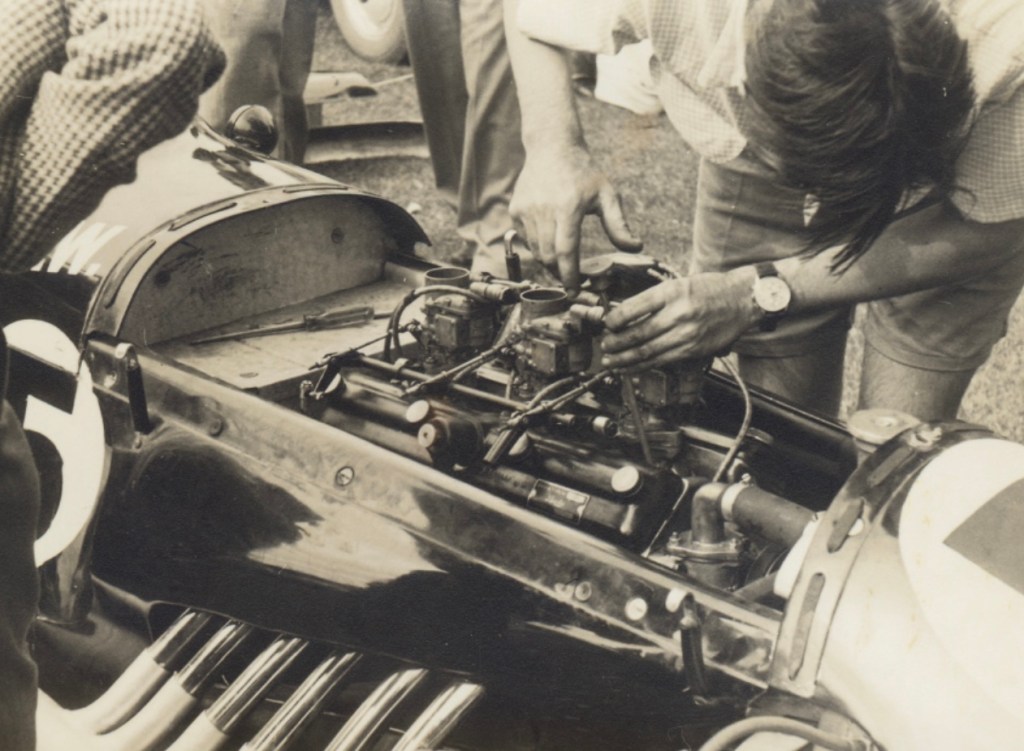

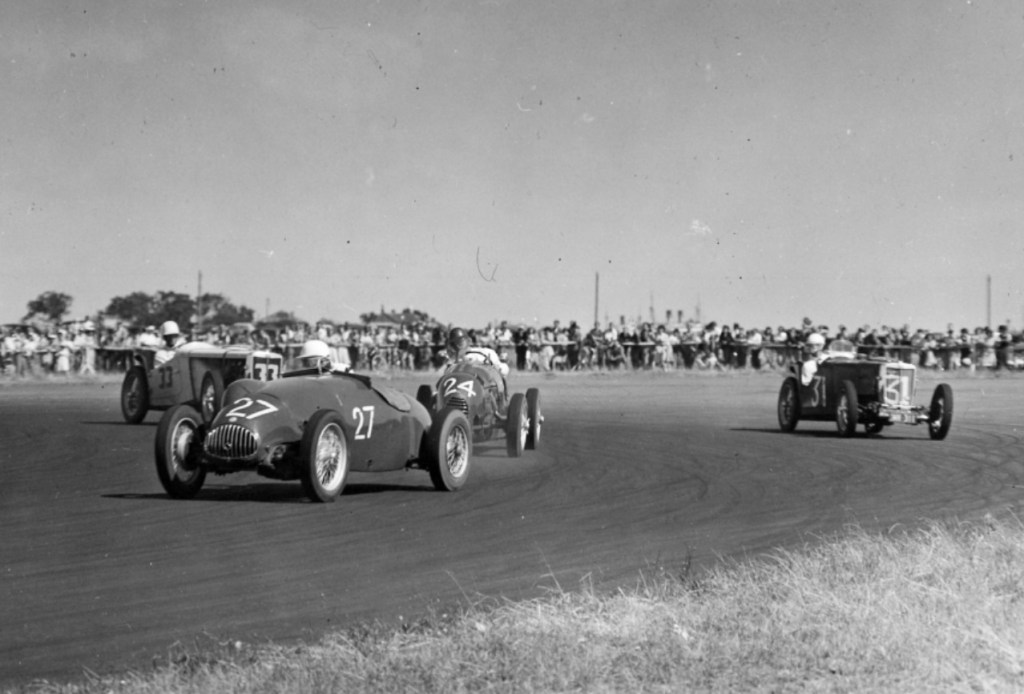

I’m not sure of the full content of that one yet, but my historic bits are a short piece on the museum, a ten-pager on the Tasman Cup from 1964-69. This is the first of two parts and has many ‘unseen’ photos taken by John Ellacott and Paul Cross. There is also an eight-page under-the-skin piece on Jim Richard’s Murray Bunn built Ford Falcon Hardtop Guney-Eagle 351 sports sedan. This one has Auto Action photos taken in the day that have never been published. It’s amazing what lurks in our files! Finally, Lord Alexander’s Hesketh outfit won its one and only championship F1 race, the Dutch Grand Prix in June 1975 . We have a two-page look at the unlikely but totally professional Peer, Bubbles Horsley, James Hunt and Harvey Postlethwaite.

Photo Credits…

M Bisset, Holden, David Zeunert Archive

Tailpieces…

This coach-built, immaculate HR Hearse caught the eye.

The skeleton in the front seat was predictable enough, but the Ford banner atop the coffin in the rear was amusing to the Blue Oval Brigade present!

Finito…