Frank Matich’s 5 litre, quad cam, 580bhp Repco V8 powered sports racer ‘SR4’ was one of Australia’s most powerful and the most successful sports-racer car ever built…

Here Frank charges the big bellowing racer across the top of Mount Panorama during the 1969 Easter Bathurst meeting. The circuit is wild now, it would have been staggering to guide this missile around the circuit then, its surface and safety features, note the proximity of eucalypts on the tracks edge, not quite what they are now!

Paddock shot of SR4, Calder 1969, some of the competition were more recent than this group! (Ian Pope)

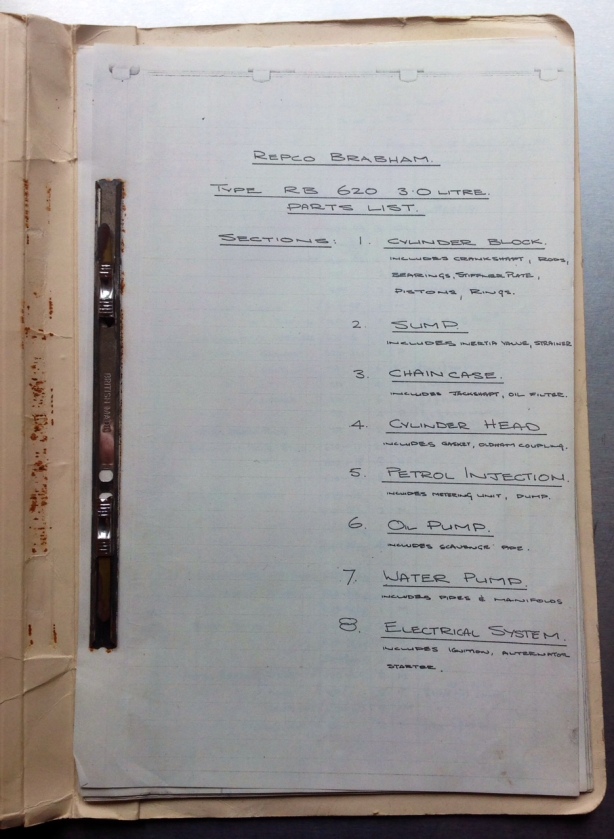

Introduction…

Built for the 1968 CanAm series, both the chassis and engine were late so Matich didn’t ever follow up his exploratory 1967 CanAm part-season in his 4.4 litre Repco powered SR3, instead belting the local opposition into oblivion with the SR4 in 1969.

First raced at Warwick Farm on 1 December 1968, Matich won the 3 round 1969 Australian Sportscar Championship with a perfect score; wins at Warwick Farm, Surfers Paradise and Sandown, in 2nd place was West Australian Don O’Sullivan in Frank’s old SR3 Repco. In between he raced in front of thrilled crowds who were drawn to see the fastest car in Australia regardless of category.

‘The car was last raced about May 1970 at Warwick Farm, Frank was second to Niel Allen’s Elfin ME5 Chev, he drove the car gently as the engine had a vibration which a subsequent tear down at Repco revealed was the front of the crank cracking’ recalls Derek Kneller, an ex Matich engineer/mechanic from 1969-74. ‘The car was kept under a dust sheet in the Artarmon (Sydney) workshop until after the Tasman Series in 1971 when FM asked us to clean it up, it hadn’t been used for 8 months, we delivered it by trailer, still with the engine fitted, to Repco in Maidstone, Melbourne’.

SR4 was then used as a display piece, never to be raced again until the ‘modern era’ when it was restored by its owner, former Repco engineer Nigel Tait who has had a connection with the car since its construction. This bulk of this article is by Nigel, the photos are mainly from his vast archive of shots of this wonderful, very significant Australian racing car.

This piece is a biggie and comprises numerous parts;

.Historical context for the building of SR4; the earlier SR3 (3 chassis) in particular a summary of its 1967 CanAm program

.Biography of Nigel Tait

.Nigel’s story of the cars design, construction, specifications, race record and restoration

.SR4 specifications

.Etcetera; SR4 related snippets

.How competitive would SR4 have been in the ’68 CanAm had it crossed the Pacific as originally intended, this section designed to stimulate discussion amongst Australian enthusiasts of the period!

.Matich Cars; list of all cars built by FM’s business

Early shot of SR4 when still fitted with a ZF ‘box, LG Hewland fitted later in the year, suspension and engine as per text (Repco)

Frank Matich and Matich Cars…

Matich was one of Australia’s drivers who was as quick as the best in the world during the early sixties Tasman 2.5 Formula when the locals went head to head with the internationals in near enough to identical cars.

Frank then focused on sportscars from 1966 to 1969, as we shall see.

In 1969 Matich returned to single-seaters, F5000 and again proved to be the equal of if not better than the best in the world winning races in Australasia and the US before retiring at the end of the ’74 Tasman Series.

In addition, his team designed and built world class sports and F5000 cars from late 1966 to early 1974. His cars won races after that, John Goss took an exciting 1976 Australian Grand Prix win at Sandown in an A51/3 Repco chassis for example.

A list of the cars Team Matich built is at the end of this article.

I have written some pieces about Frank before, rather than than provide background again click on these links, the best quick career summary is this one, sadly an obituary;

See this pictorial though;

This monster piece is mainly about his F5000 racing but also includes earlier career material;

And this one is about his 1966 Elfin 400 Traco or the ‘Traco Oldsmobile’ as he named it;

Elfin 400/Traco Olds: Frank Matich, Niel Allen and Garrie Cooper…

The latter article about the Elfin 400 is the most important in the context of the Matich SR4, the 400 evolved into the Matich SR3, the SR3 to the SR4…

Matich SR3…

The first Matich SR3 Traco Olds was built in late 1966 to replace the Elfin 400 Traco Olds upon which it was based. According to some close observers, including at least one of FM’s mechanics the SR3 chassis was ‘tube for tube’ identical to the Elfin 400 albeit strengthened with the learnings of racing the car from the start of ’66 until it was sold to Niel Allen later that year.

The aerodynamics of the SR3 were entirely different to Garrie Cooper’s 400 design and are a function of the 400’s shortcomings and FM’s ongoing absorption of global design and aerodynamic/styling trends. The 400’s ‘aero’ deficiencies are examined in detail in my Elfin 400 article above.

This section is not a detailed article about the 3 SR3’s FM’s team built but rather a summary to provide context about the SR4’s build.

The first CanAm Series was won by John Surtees in a Lola T70 Chev in 1966 but there had been professional sportscar races on America’s West Coast back into the 1950’s.

During the 1.5 litre F1 years (1961-65) big brutal ‘Group 7’ sportscars powered by ever increasing in size ‘stock block’ American V8’s thrilled crowds with their speed on both sides of the Atlantic. The best of the worlds drivers contested the races, rich prize money the reward for success in events of 200 miles, GP length, duration.

Frank Matich had ample opportunity to hear first hand during the Tasman Series about the US scene from Jim Clark, Graham Hill, Jackie Stewart, Bruce Mclaren, Phil Hill and Jack Brabham all of whom contested CanAm races, not least Bruce who had also been building Cooper based cars and McLaren/Elvas to contest the races for years.

Matich determined to contest the 1967 CanAm to test his mettle against the best in the world knowing their was little point being ‘king of the kids’ in Oz. The reality is that whilst the domestic single-seater Gold Star competition had some depth, in sportscars their was little at all.

Naked SR3 Repco in the Road America paddock, 1967. Spaceframe chassis RBE ‘620 Series’ 4.4 litre, SOHC, Lucas injected, 400bhp V8 (Friedman)

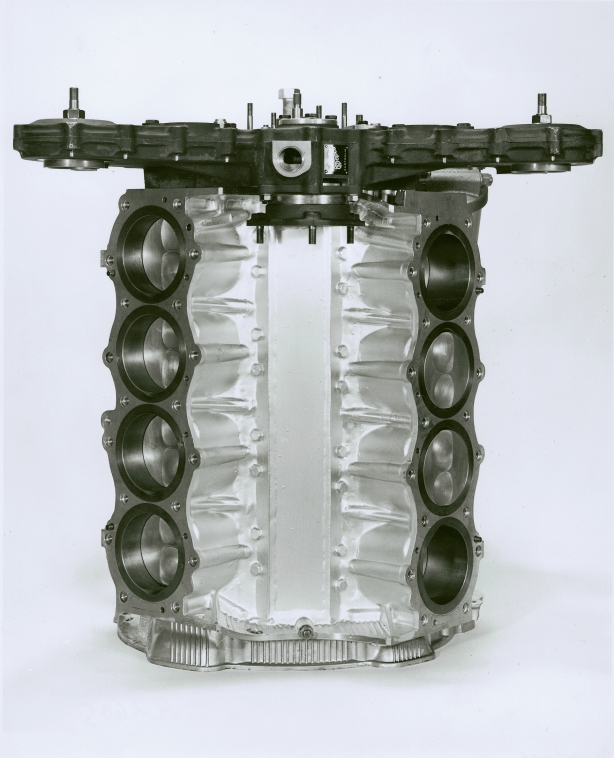

Repco were also finally selling their engines to customers (as against providing works engines to Brabham with which Jack had contested the ’66 Tasman and won the ’66 F1 World Title) so Frank figured the 4.4 litre, sohc, ‘620 Series’ 400bhp V8 would be a much more competitive proposition than the highly stressed aluminium, pushrod Olds V8 engines he used in the Elfin 400/Traco Olds and his first SR3.

It was a big ask.

McLaren had persevered with the lightweight aluminium Oldsmobile engines until 1966 when he fitted 6 litre cast-iron Chevs to his spaceframe McLaren M1B. His 1967 M6A, a joint design effort between Bruce and Robin Herd were stunning, simple, monocoque cars superbly driven by Bruce and Denny Hulme to 5 wins from 6 races with Bruce taking the drivers and McLaren the manufacturers titles. The ‘Bruce and Denny Show’ rolled on thru to the end of ’71 when Porsche finally ended the party.

Matich raced two SR3 chassis in a limited campaign in the ‘Non Works McLaren’ class!

As a warm-up Matich won the RAC Trophy at Warwick Farm on May 4 and the ‘Australian Tourist Trophy’ at Surfers Paradise on 21 May 1967 from Alan Hamilton’s Porsche 906 and Glynn Scott’s Lotus 23B Ford. The SR3 was Olds powered.

Matich SR3 Repco leads a group of cars, John Cannon in a McLaren M1B Chev the car behind him, Road America 1967. FM retired with a stone thru his radiator on lap 15, Denny Hulme won in a McLaren M6A Chev (Friedman)

The 1967 CanAm started at Road America, Wisconsin on 3 September and finished with the sixth and last round at Las Vegas on 12 November, the well oiled McLaren Team crushed the opposition winning all but the final round which ’66 champion John Surtees took in a Lola T70 Chev.

McLaren deservedly won the title from Hulme despite Denny winning 3 rounds (Road America, Bridghampton, Mosport) and Bruce 2 (Laguna Seca, Riverside).

Matich and his small team contested the Road America, Bridghampton, Laguna Seca and Riverside rounds. Fundamentally the car, sweet handling as it was, was outgunned. Its 400bhp Repco having way too little grunt and lacked the reliability for these Grand Prix length sprints of 200 miles.

At Road America the SR3 qualified on 2:22, 18th to McLarens pole of 2:12.6, retiring on lap 15 with a radiator holed by a stone. In the glorious Hamptons in New York on 17 September he qualified 15th 1:33.49 to Hulme’s 1:29.85, but again DNF this time with fuel starvation.

Frank’s team missed the Mosport, Canada round on 23 September which Hulme’s M6A won.

In California for a couple of races FM gridded 13th at Laguna Seca on 1:05.07 to McLarens blistering pole of 1:02.69, a race Bruce won. Interestingly the Ferrari P4/350 CanAm (a P4 lightened, modified and increased in capacity) did their first ’67 event, Amon finished 5th but qualified behind Matich in 16th on 1:05.77.

Matich and Amon, the latter in in David McKays Ferrari P4/350 CanAm had some sensational scraps that Australian summer in the sportscar races which supported the Tasman Series rounds with the Repco powered car demonstrably quicker than the exotic, long distance derived V12 powered Ferrari.

Matich, wife Joan his mechanics, Peter Mabey at left and Firestone technicians on the Riverside pit apron, CanAm 29 October 1967, John Surtees Lola T70 Mk3B Chev behind. Bruce won the race, Matich crashed and Surtees DNF with ‘rear end’ problems (unattributed)

Still in California, at Riverside on 29 October McLaren won, Hulme was on pole with 1:39.30, Matich 20th on 1:45 and Amon 15th on 1:44.40. Frank crashed out on lap 20. With that the team decamped back to Oz to prepare for the Tasman Series encounters with Amon, with Matich winning each of these battles. Click here for an article on the Ferrari P4/CanAm 350 ‘0858’ inclusive of the Matich/Amon battles;

Jack Brabham, Brabham BT19 Repco and a very young Nigel Tait at the Sandown Tasman meeting, the second race outing for the first ‘RB620’ engine, 2.5 litres in Tasman spec, 27 February 1966. The young engineer had just graduated from the Royal Melbourne Institute of Technology and has ‘landed on his feet at Repco Brabham Engines. Tait maintains this car for Repco all these years later. One of a kind BT19 is Jack’s 1966 championship winning mount (Australian Post)

Nigel Tait…

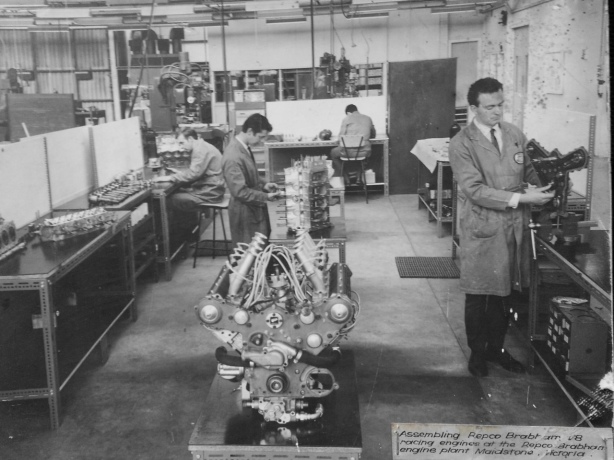

Having qualified in Mechanical and Automotive Engineering at Royal Melbourne Institute of Technology Nigel commenced work at Repco in 1966 as an Engineering Cadet. His first placement, you can be lucky!, was in the engine laboratory in Richmond where the Repco Brabham engines were built and tested. He helped to plan and implement the move of the Repco Brabham project to another plant, in Maidstone, this involved manufacture of shadow boards for the new machine tools being installed for further manufacture of the racing engines.

He progressed to assist the head engine builder (Michael Gasking) with assembly, dynamometer running of the engines and worked on BT19 (Jack’s ’66 championship winning chassis) when it was being prepared for the ‘620 Series’ 2.5 litre Tasman V8 for Jack Brabham to use at the ’66 Sandown Tasman meeting. He also worked with other project engineers on test and development of the range of engine components being manufactured at the various engine parts manufacturing factories of the Repco empire for fitment to the race engines.

These project engineering tasks continued for some years and included a 4 month transfer to England to work in some of the companies to which Repco was licensed.

By the mid 70’s Nigel was running the engine laboratory in Richmond, which had become the Repco Engine Technical Centre. In conjunction with the University of Melbourne he supervised a major Federal Government contract for the testing and evaluation of diesel and petrol engines running on alcohol fuel mixtures. He also spent some years as chief engineer of the engine parts plant at Richmond before returning to the engine laboratory, which became his base as Chief Engineer of Repco’s Engine Parts Divison.

He was closely involved with original equipment product development and sales to local car companies and travelled throughout Australia and New Zealand extensively giving product knowledge lectures and writing technical articles. He made a significant contribution to the engine component design sections in the Repco Engine Service Manual (later to be reissued as the ACL Engine Manual).

The division was sold to a management buyout group in 1986 and became ACL (Automotive Components Limited). Nigel was one of the 9 in the buyout group and continued in the role of chief engineer until his retirement in 2005.

The Matich SR4: One of Australia’s most famous and successful racing cars. Here Matich slices the car, with typical pinpoint accuracy into Warwick Farm’s Esses, 4 May 1969. Interesting in an historic context, hi-wings were banned during the Monaco GP weekend of 18 May…

Overview..

Frank Matich had already won the Australian Sports Car Championship four times by the time he commenced work on the SR4; he won in a Lotus 19 in 1964, Elfin 400/Traco Olds in 1966 and in the Matich SR3 in 1967/8.

He had competed in the USA in 1967 as recounted earlier. His dominance of sports car racing in Australia was legendary and led to the catchphrase: ‘Doing a Matich’. (Pole position, winning, fastest lap time and lap record). Frank’s record with the SR4 is impressive. He raced at Bathurst, Calder Park, Catalina Park, Sandown, Surfers Paradise and Warwick Farm.

SR4 took nineteen starts for 15 wins, one second with eight outright lap records and winner of the 1969 Sports car Championship.

SR4 Owners..

Rothmans Team Matich (1968-1970), Repco (1970-1986) Automotive Components Limited (1986-2005) and Nigel Tait (from 2005)

SR4 in Repco’s Maidstone, Melbourne workshop in 1971, great shot of the nose/spoiler assy and carefully ducted, both ‘in and out’ of radiator, suspension as per text. Note front lights mandated by Oz rules (Jay Bondini)

Build, sponsorship and first ownership..

It’s not certain who actually owned the SR4 as built. It was constructed at Frank Matich’s workshop in Sydney and as far as I know largely funded with sponsorship from Rothmans (tobacco) and perhaps others. The engines belonged to Repco.

Some time after the first logbook was issued from CAMS it was mislaid and Frank wrote to apply for another, stating ownership as ‘Rothmans Team Matich’. In his book ‘Historic Racing Cars in Australia’ John Blanden wrote that ownership transferred to Rothmans while the car was still in competition, that’s the period from December 1968 to January 1970. It’s also known that Rothmans made a practice of owning the cars that Matich raced under their sponsorship.

The car was retired in early 1970 so that Frank could concentrate on F5000. Repco wanted the car to use as an advertising tool and in return, it is my understanding, that an arrangement was made for the car to be transferred to Repco’s ownership in return for ongoing supply of engines and sponsorship for F5000, these being made at the old Repco Brabham plant in Maidstone. (That’s where I started work for Repco in 1966 as a cadet engineer). This division was renamed Repco Engine Development Company (REDCo) under General Manager Malcolm Preston.

Frank Hallam, Repco Brabham’s General Manager, and incidentally my first boss, had by then been transferred to Repco Research, and one day acidly described to me his life out there as ‘a career careering between obstacles’. He wasn’t happy about being put out to pasture.

Shot as above after delivery to Repco in Maidstone, Melbourne. Note wing spec then, it would be interesting to know which meetings it competer in this spec, noting changes were ongoing apart from those mandated by the FIA from the ’69 Monaco GP weekend, hi-wings banned from then (Jay Bondini)

Anyway, the car was sent down from Sydney to Repco in late 1970 (I was working for Repco in England at the time so can’t be sure of dates) and was first placed at the Repco Apprentice Centre in North Melbourne. Then it was sent to Maidstone to rest, for some years, in a room next to the REDC0 drawing office. It was in a forlorn state with an empty engine and at the time of little interest to Repco or anyone really.

Anyway once REDCo had closed down after F5000 had finished (at least for Repco) I had the car and all of the Repco Brabham/REDCo drawings and files and other hardware transferred to our Richmond engine laboratory that I supervised. Another division of Repco was to occupy the Maidstone building but not the two engine dynamometer cells, which I was to run, not very successfully as it turned out, on a commercial basis.

By that time Don Halpin had transferred from the Maidstone plant of Repco Engine Parts to our Richmond laboratory and he undertook a cosmetic restoration of the car so that Repco could use it for trade displays and shows etc. It was not a running vehicle at this stage since there was no engine, only a few parts to make it look OK.

Various divisions of Repco used the car for displays as intended and the car also spent quite some years on public display at the Birdwood Museum in the Adelaide Hills, and then the Auto Museum in Launceston, Tasmania.

From Repco to ACL..

During the early 80’s Repco underwent considerable change in its upper management and ownership. (You could read ‘corporate raiders’!). By about 1985 Repco had sold off some of its manufacturing divisions, Repco Research, the Brake and Clutch Division and the machinery manufacturing division and it became clear that manufacturing was of no interest to the Board. Clearly the factories manufacturing engine parts in Melbourne, Brisbane and Launceston were next to be offloaded. Indeed while the Repco Board instructed the Divisional General Manager of this division to advise his staff that it was not for sale, it on the other hand instructed him to find a buyer!

So in August 1986 a management buyout team comprising 8 of its senior staff (including myself), and our Divisional General Manager, purchased the whole division from Repco. At a price of $A28 million and with very little equity and huge borrowing, the team pulled off what was the largest management buyout of its type in the country’s history. There were almost 1,000 employees spread over 5 states. My role was to continue as chief engineer.

The new company adopted a name that was actually one of Repco’s 1960’s takeover targets, ACL, and the new company became ‘Automotive Components Limited’. (Repco had no need to use this name and allowed its use by us).

All of the assets of the then Repco Engine Division were transferred to the new company, these included the Repco Brabham BT19 and all associated drawings, items and trailer and also the Matich SR4 which was still in its cosmetically restored state. So the Matich became the property of ACL from August 1986. ACL continued to display the car publicly including the museum in Launceston and other venues.

SR4 in the Birdwood Museum, Adelaide Hills, at this stage the ‘cosmetic’ restoration had been done by Don Halpin as per text, car not ‘a runner’ (The Roaring Season)

Niel Allen’s ex-Matich Elfin 400 Chev (named Traco Olds by Matich) ahead of FM’s SR4 and Bevan Gibson’s ill-fated Elfin 400 Repco, sadly Bevan died during this race, Easter, Bathurst 1969. This event is reported in full in the Elfin 400 article, a link for which is at this articles outset (Dick Simpson)

An engine was found..

Towards the mid to late 90’s with the growth of interest in historic racing there were numerous approaches made to ACL to buy it. These were made direct to the Board or sometimes to myself, and always we advised that the car was not for sale, but would be restored once an engine could be located.

Luckily that did happen. Aaron Lewis, who is prominent in historic racing circles and the owner of some magnificent cars, advised me that Les Wright of Sydney had a 4.2 litre Repco Brabham engine in his Brabham Buick. CAMS had advised that this was not the way the car was originally raced and that Les would need to remove the engine and obtain the correct Buick engine to obtain a CAMS permit to race the car. On behalf of ACL I bought the engine for $30,000. Les ran it on the floor and it worked pretty well so was transported to Melbourne. This was circa 2000.

At last we had an engine and I was able to have the car brought back to life. Jim Hardman (ex F3 racer, mechanic, engineer and builder of the superb Hardman F2 cars of 1980) undertook this restoration, which was essentially to make it mobile, look good and be safe for display and demonstration running. This work was undertaken by Jim at his rented area within Heckrath Engineering in Cheltenham and paid for by ACL.

I sent the body to Richmond TAFE who had offered to spray it. It turned out to be a very poor job where even the colour was wrong and I had to engage a panel beater near us at Maidstone (Houdini) to do it again. More about the colour later.

Once in running condition at Heckraths Jim Hardman became the first person to drive the car for over 30 years. Albeit this was in Bricker Road, Cheltenham on a quiet weekend morning, a quick blast lest the local police took interest! More ‘legal’ trials were held at Calder in outer Melbourne, with Jim doing most of the driving though I squeezed myself into it several times.

Subsequently the car was displayed many times from around 2002 to 2005, at Motorclassica, the Australian Grand Prix, various circuits and trade shows and even at a Repco function.

Jim made up a seat for me and I took it to several meetings at Eastern Creek, Winton, Phillip Island etc and we also used it as a display vehicle for our numerous company functions. When Jim drove it at Phillip Island it dropped valves in both heads (probably stones down the intakes) and we had to undertake a fairly extensive rebuild. (Not having wire screens on the inlet trumpets was a bad mistake, as others have also learned).

Repco engine assy area, Maidstone factory, Melbourne in early 1968, the engine towards the front is a 3 litre ‘860’ F1 engine, behind are ‘760s’, capacities unknown (Repco)

Engines..

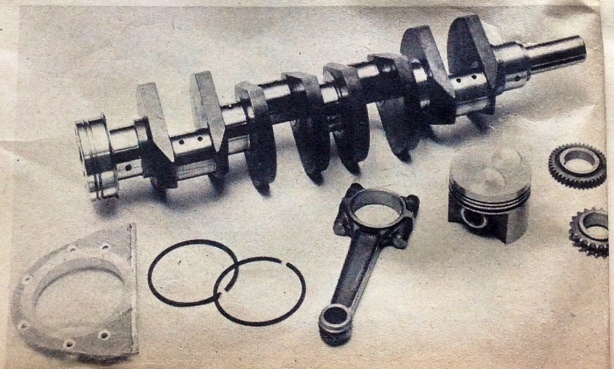

The whereabouts of the original 5 litre ‘760 Series’ engine used when Frank Matich raced the car is unknown. I doubt that it came back to Repco. There is some suggestion that it resides somewhere as the base of a coffee table and I hold out hope that one day this engine might come to light, if only as an important part of the car’s history for the next generation.

4.2 litre: I’ve already explained how we came by the 4.2 litre engine ex Les Wright. The 4.2 litre ‘760 Series’ quad cam engines were made only for Indianapolis for Jack Brabham and for Peter Revson. I think there may only have been two or perhaps three, the records are not clear. The engine in the ex Revson BT25 of Aaron Lewis is undoubtedly the one from that car. Sir Jack Brabham told me that one of his engines used in his 1968 BT25 Indy car that he lent to Goodyear ‘disappeared’ and I have a feeling that the engine I have might be this one.

It is as original though as a result of the dropped valve at Phillip Island one of the bores had to be honed slightly oversize to remove some marking and hence the piston and rings in this cylinder are a little larger. Otherwise the engine is as run by Les and still has the same cams etc. It runs on Avgas. I use 50 cc of two stroke oil per 20 litres of Avgas for lubrication of the metering unit.

Its output would be around 550 BHP at about 8,000 RPM but I have never pushed it beyond 6,500 RPM. I have rebuilt it a second time just as a check and little work was needed.

Peter Reilly assembling an ‘860’ 3 litre F1 engine valve train assy, the engines problem area!, refer to the text, beautiful workmanship clear. ‘860’ the only gear driven cam engine, ’20 and 40′ Series driven by chain (Repco)

5 litre: Some years ago I discovered that I had enough parts from which to commence build of a 5 litre ‘760 Series’ engine. I had a block of the right type (to take the Cooper rings rather than head gaskets). Crankshaft Rebuilders made sleeves and a crankshaft, rods were made by Argo, pistons by Special Pistons Services and the heads that I had were completely rebuilt at Head Stud Developments. Luckily I had the gear casings all of the gears (the quad cam engines have gears, not chains) and a spare sump of the right type with integral oil pressure and scavenge pumps.

Build of this engine took me about 2 years including the time for manufacture of the parts by Crankshaft Rebuilders. A much larger than original torsional vibration damper was made for me by Tuffbond in Sydney. Minimizing crankshaft torsional vibration protects the valve gear and camshafts etc. as well as being better for the crankshaft itself.

Actually the engines used by Frank were of 4.8 litre capacity, the bores being reduced slightly to overcome sleeve cracking due to being too thin. I have made my engine to true 5 litre capacity with the steel sleeves and was able this way to utilize off the shelf ring sizes. Also I had the rods made to 6” length which enabled the use of much shorter and lighter pistons in keeping with modern engine design practice.

The result is a very nice engine with noticeably more torque. Though I have not had it on a dyno it would no doubt see around 600 BHP, though as with the 4.2 I do not use any more than 6,500 at which point the cams are in and there is plenty for me!

The 5 litre encountered what I thought was a mild overheat at Geelong* in 2014 so I have rebuilt this over 2015/6. There was no bore damage but the crankshaft needed grinding and otherwise the engine is in good condition and ready now for further use.

*Note: I have learn’t that apart from needing a better bleed for the cooling system (now done) I have let the engine rev too slowly upon first start up. The water pump speed is only half engine revs so now I run the engine at 2,000 RPM from any cold start to make sure the coolant is flowing properly.

Reverting to the 4.2 litre engine in Aaron Lewis’ BT25, it is currently in build and it would be nice to see it running. (at the time of uploading this article Aaron has run the car at Eastern Creek, Sydney) At this stage the two quad cam Repco Brabham engines (and now Aaron’s) that I have for the SR4 are the only Repco quad cams that run, anywhere.

I have nearly enough parts to commence a third engine build but this would have to be with a block that uses head gaskets and these would need to be re-torqued thus would need either a dynamometer run or engine removal from car after first run. Or with luck I’ll find another Cooper ring type block.

Sale from ACL to Nigel Tait..

I was still hard at work as ACL’s Chief Engineer up until my retirement in July 2005. Consequently outings with the car and indeed also the BT19, were rare and had to fit in with my work rather than being at my will.

With retirement imminent it became obvious that with no one else at ACL interested in the two cars we’d have to consider their future. Repco had a first option to buy BT19 and it was decided to sell this back to them around June 2005, for $1.3M. I had been looking after it since it was bought from Jack Brabham in 1970. Repco asked if I would continue to be its carer/minder, which I do to this day.

The Matich was to be sold and my bid was the highest, thus securing for me a car that i’d been looking after virtually since its acquisition by Repco. I paid my company $160,000 for it and the various spares and display material and engines, (including the 3 litre quad cam ‘850’ diagonal port engine). I also purchased the trailer that was made for us by MRT Trailers, for $10,000.

As earlier mentioned the first restoration by Don Halpin was to allow the car to be on static display.The second, once we had the engine from Les Wright, was by Jim Hardman and resulted in the car’s first outing in 30 years.

Once I had purchased the car in 2005 Jim advised that we should undertake a complete bare frame restoration and rebuild. Jim still had the facility at Heckrath’s and i was able to devote some time to the menial tasks such dismantling, cleaning the frame ready for spraying and running around getting parts etc as needed.

Chassis, big and butch to take the big Repco’s power and torque, quoted weights of ’68 McLaren M8A and Matich SR4 similar. Given the Repco engine was way lighter than the ally’ block Chevy of the M8A, the difference in weights is a bit of a mystery as Tait quotes the Matich bare frame at 38Kg (Tait)

Hardman replaced all of the aluminum skins, undertray, all firewalls etc and repaired and strengthened the frame as needed. In fact there was no real problem with the frame, one part of the outrigger on one side had partially cracked and the bar that was the top mounting for the seat belt upper harness was too small. Everything else was terrific. A great testament to its builder, Henry Nehrybecki. I photographed all stages of the restoration and rebuild which took exactly 6 weeks from the May Winton meeting to being ready for Speed on Tweed later that year.

Wishbone front suspension, coil spring/Armstrong damper and ventilated front discs, steering rack also in situ, Matich designed, CAC cast (Tait)

Heart of the matter in place as is Hewland LG600 ‘box, car first raced with a ZF. Rear suspension period typical; single upper link, lower inverted wishbone, coil spring/dampers (then Koni now Armstrong) and twin radius t rods for fore and aft location. Note big oil reservoir and beefy rear chassis diaphragm above ‘box (Tait)

Proud custodian Nigel Tait with SR4. Jim Hardman an outstanding race mechanic/engineer and car builder ‘in period’ and now a restorer of similar calibre (Tait)

Multiple Australian Champion John Bowe expressed interest in doing a track test for ‘Unique Cars’ magazine. This was shortly after our 2006 rebuild. He planned on a run at Calder for this but that day could not be scheduled as intended. Instead John’s first drive of the car ended up on the road circuit at Murwillumbah’s Speed on Tweed. Organised by Roger Ealand, who so sadly we have just lost, this event ran for several years and in fact culminated in its final event with a stage of the Repco Rally being held also on the same circuit, but at night.

John drove the car for its 4 or 5 runs but even after the first he requested some suspension changes, which had an immediate effect. Subsequently John’s planned track drive at Calder came off and he drove numerous laps following a camera car and some at speed. A successful day and John loved the car. His only request was for the height of front and rear to be changed to change the undertray height to be higher at the back to improve downforce.

My Licence.

I have a level 2S licence. In my earlier days of racing it was the equivalent of a Level 1, but some 25 years ago I lost one eye resulting from an infection during a skiing holiday in New Zealand. That’s one reason why my driving is limited to display regularity and super sprint etc but the other reason is quite pragmatic; there are few drivers around, and I’m not one of them, who could handle this car to its full potential. With over 600 BHP and a weight of just 625kg the car commands great respect.

Start of the fateful race which took Bevan Gibson’s life, Easter, Bathurst 1969. Gibson in Bob Jane’s red #6 Elfin 400 Repco, Niel Allen #2 alongside in his Elfin 400 Chev and Matich to the right in the hi-winged SR4 (Wayne McKay)

Contact with Frank Matich..

I took the car to Eastern Creek in Sydney on several occasions in the years before and after its bare frame restoration in 2006.

Frank was at some of these meetings and was delighted to see and hear it in action. He was full of praise for the standard of the restoration and for my efforts in bringing it back to life. We spent quite some time discussing technical aspects of the car and he noted that someone had replaced the Koni shock absorbers with Armstrongs, a pity he said because he set the Konis with very little bump and mostly rebound, something that I can’t do with the Armstrongs. Frank was apologetic that somehow his people had done a cleanup in his factory and had discarded many spares including patterns and wheels etc that he would have given me. These were good conversations and it was fun also to meet his daughter Katrina and his granddaughter Paige and to have photos of all with the car. He said that he was glad the car was in good hands.

Unfortunately relations deteriorated somewhat in Frank’s latter years when he claimed that he had not sold the car to Repco and wanted it returned! This after a period of over 30 years since Repco’s acquisition during which there had been no communication from or to Frank and with the car having been through two changes of ownership.

Subsequently Frank’s attention was drawn to the reference in John Blanden’s book stating that ‘It initially ran with Rothmans signage and subsequently Rothmans acquired ownership of the car’.

There was no further communication on this issue. It was disappointing but didn’t diminish my admiration for Frank as a brilliant driver and one of the great legends of Australian motor sport. To this day I can recall the car running at Sandown and steaming into Peter’s corner (I was an official there) with all brakes locked up, tyres smoking when the throttle had apparently stuck. That was a great era.

Matich ‘locks em up’, a stuck throttle the cause, on Sandown’s pit straight just before Peters/Torana corner in 1969 (Tait Collection)

Henry Nehrybecki..

Henry was the builder of the car, at least the chassis and suspension and no doubt he had a team of helpers. Indeed I’ve heard that some of the time during the build Henry was not well and Bobby Britton (of Rennmax Engineering) may also have been involved.

I had numerous discussions with Henry in the early days after we got the car going and took it to Eastern Creek. He was thrilled the car was back in action after being out of circulation for 30 years. A small coincidence is that Henry’s granddaughter Gabrielle lives in Melbourne and is in the same friendship group as my daughter and her friends.

Derek Kneller; ‘Henry drew and fabricated the chassis, the conceptual design of which was Frank’s and his, Bob Britton was also involved. The chassis was then transferred to Franks facility, the Castle Cove BP Garage in Eastern Valley Way, which comprised a ‘servo’, the race ‘shop and Firestone racing tyre warehouse. It was in late ’69 that FM switched from testing and selling Firestones to Goodyear’.

John Mepstead and Matich ponder the SR4’s brakes in the Sandown paddock after its big brake lock-up. Mepstead an ex-Repco mechanic/engineer hired by FM to look after the car in ’69 (Tait Collection)

‘Peter Mabey assembled SR4 at Castle Cove, he had been with FM for some years including the SR3 race program in the ‘States. After that Peter looked after the Servo side of the business before returning to the race side of things on the F5000 program with me. SR4 was maintained and race prepared in 1969 by Tony Williams and John Mepstead on the chassis and engine respectively’.

Others to drive the Matich SR4..

Apart from Frank there have been no others to drive it in any competition except John Bowe and Laurie Bennett. We will not count my many demonstration drives, super sprints and regularity events and even in the Top Gear event at the Melbourne Showgrounds.

As earlier mentioned John drove it at Speed on Tweed just after its 3rd restoration. Laurie drove it at Mallala in one Super Sprint. His Elfin 600 had expired and I let him take it out. Effectively he won this having started last on the grid and passed all of the others by the last lap, while being stuck in 2nd gear.

Bill Hemming and David Hardman (Jim’s son) also enjoyed some practice laps at Mallala and Winton respectively. Also Brian Sampson who would have loved to own the car took it for a few laps at Winton after the third restoration. He really enjoyed it however we had a problem with a badly set up throttle mechanism which made it difficult to drive.

The body was made in Sydney by JWF Fibreglass. It was not intended to be this way. The plan was for it to be made from aluminum and they went a long way towards completing this but the task became too hard and too slow. What had been made was used as a mould for the fiberglass body. This was one of the reasons the car didn’t go to the 1968/9 CanAm, the other was that Repco was late with the engine.

When we restored it at ACL it was strengthened with some extra layers internally as it was very flimsy and cracked in many areas. It’s a little heavier but still OK.

I’ve mentioned earlier the colour. After the debacle of the Richmond TAFE attempt we’d lost the original colour since every panel was by now the odd purple colour, so there was no colour match possible. Houdini Panels suggested an off the shelf colour common to a road car of the time and as it looked more vibrant and could be retouched more easily I chose this.

It appears there were two bodies, or at least two rear sections. When the car raced at the Easter Bathurst meeting Frank had the very high wing and it was attached to the rear hubs by uprights that went through holes in the body. After Bathurst the car reverted to low wing, no wing and various iterations in-between, but always body mounted. The wing on the car now is about 300mm above the rear deck and I am not sure if the car competed in this way or if the wing was experimental in the latter stages of the car’s life with Frank.

Just last December (2015) I found another rear body section for the car. It came to light in an outer suburban junk yard along with the body from Colin Hyams’ T190 Lola F5000. How these came to be at this property is something we’ll never know. Anyway I bought the Matich rear body (for much more than it is worth), as it is definitely the one Frank used at Bathurst, with the holes for the wing supports and is the original dark blue. It still has the Repco and other stickers on it. I don’t intend to use this but it would fit straight on still having the original brackets.

Chassis number..

The chassis was number 07. When I decided to have a brass plate made I asked Henry if he knew what the chassis number was and he advised it was number 1 so I had the plate made this way. He was probably referring to the fact that it appears another chassis was made, very similar to mine, but never actually made into a car. So Henry was thinking about SR4 chassis of which mine was the first. I suppose I could re-engrave the plate on my car.

SR4 in the Surfers Paradise paddock, note the car is now fitted with a Hewland LG500 ‘box rather than the ZF in the earlier rear shot (Tait Collection)

Gearbox..

The car was made with a ZF. It seems the side plates of this gearbox were not strong enough and also the 4 speed Hewland LG500 that replaced it was more common at the time and ratio changes were easier. There is a reverse but to set up the adjustment to get this compromises engagement of the forward gears so it does not go into reverse at all. I don’t have any spare ratios. The only places 4th gear is used is at Eastern Creek, Calder, briefly, the back straight at Pukekohe, NZ and the Grand Prix circuit at Albert Park. Also Sandown and Phillip Island. Given a good straight the car would reach 200 mph.

Derek Kneller; ‘I helped fit the Hewland LG gearbox to SR4. We were converting Frank’s F5000 M10A McLaren to M10B spec, i built the first of these at McLaren’s before leaving the UK for Oz. A DG300 Hewland was fitted to the M10A, the LG was popped from the M10A into SR4. Henry Nehrbecki fabricated a new rear cross-frame with a bellhousing designed by us and cast by Commonwealth Aircraft Corporation in Melbourne, we made a pattern which we could adapt for a Chev or the Repco. The change in ‘box was around November 1969’.

Tyres..

Very early in the piece Kris Matich (of Goodyear in Sydney) tried to find tyres of the original size as raced by Frank but these were no longer available. I have used Avons, supplied by Russell Stuckey and they are F5000 fronts (with treads cut by Russell) and a sports car category treaded tyre imported from Japan. The sizes are: Front: 10.5/23/15 Rear: 15/26/15

These are a little smaller in outer diameter than raced by Frank and we have set the suspension up to suit. Any difference in ratio is of no consequence.

FM after winning the ASSC round at Surfers Paradise on 18 May 1969, time for a new set of raceboots Frank! Note air reliefs atop SR4 RHS guard (Tait Collection)

Roll bar..

The roll bar height is too low for me since my seat was made for me to sit further away from the pedals. It was marginal in height for Frank. For my purposes it is OK but will need to be rebuilt in accordance with CAMS standards in due course. I think this will require a bare frame exercise.

Brakes..

These are as raced but I have slightly softer pads for quicker warm up. John Bowe felt that these might be too soft for serious racing.

Fuel tank..

The car was raced with a large bladder tank in the left pod. This was not serviceable, Jim Hardman made an aluminium tank of about 30 litres capacity and foam filled it. The car uses about 1 litre per kilometre so a larger tank would be needed for any serious racing.

Ignition..

A Lucas Opus system was on the 4.2 engine ex Les Wright though most likely Frank raced with a Bosch twin point distributor. The Opus modules are no longer serviceable. John Heckrath made up a special distributor so the Bosch module could be hidden inside the Opus unit and this worked well. There was some initial hilarity when it was discovered that the donor distributor from a V6 Holden had the wrong number of teeth for a V8! (The timing was only ever right for the first few degrees of engine rotation and had to be retimed numerous times until the oversight was discovered). More recently Performance Ignition made up a Scorcher system and this now works perfectly albeit is not as the car was raced.

Cam covers..

The car raced with cam covers designated ‘REPCO’. I built my 5 litre engine accordingly but the 4.2 litre engine, being ex Jack Brabham Indy, had ‘REPCO BRABHAM’ cast onto the top. I’ve chosen to leave it this way, i have spares of both types. (An early photo shows the car with Repco Brabham cam covers and also shows the ZF gearbox).

CAMS Certificate of Description (Australias more rigorous equivalent of FIA historic racing certification)..

For what I do with the car a C.O.D. is not needed but I was persuaded that it would be a good idea to have this so the car could be documented as raced, for future reference. A C.O.D. was obtained in 2015. It is # 0.040.03.02.

New Zealand

I have taken the car to New Zealand twice, both times to Hampton Downs, and on the first occasion to Pukekohe as well. I was included in the demonstration events on each occasion and had plenty of track time with F5000’s and other sports cars. This was especially so at the most recent of the visits to Hampton Downs where there were so few of the big sports cars entered they needed me to make up numbers, at least in the practice, qualifying and even on the warm up lap of every race! The two events were to celebrate Bruce McLaren and Denny Hulme respectively.

Importantly the Matich ran very well and was popular with the locals.

Future..

My plan is to continue with displays and demonstrations, regularity and Super Sprints as much as possible given my other passion, snow skiing. This sidelines me for most of the winter months in our small apartment at Mount Buller. I hold out hope that I can get the roll bar rebuilt soon, the 5 litre should go back in later this year and it would be nice to make another trip to New Zealand.

My longer term mission is to see the car in the hands of someone with the necessary technical ability, driving skill and passion to continue to present the car, whether racing or not, in the manner that reflects the great legacy for its terrific driver, Frank Matich and Repco for its amazing engines.

Nigel Tait June 2016

This card, and the shot just below was produced by Repco and handed out at race-meetings trade shows and the like in period (Tait)

Matich SR4 specifications…

Engine: Repco Brabham quad cam. Repco designed and manufactured ‘700 Series’ aluminium crankcase/block cast at Commonwealth Aircraft Corporation, Fishermans Bend, Melbourne.

Four valve per cylinder, DOHC, gear driven, ’60 Series’ aluminum heads designed by Repco and cast at Castalloy in Adelaide.

Lucas mechanical fuel injection system with metering unit driven from the same jackshaft which describes the distributor Port mounted Lucas injectors running at 100psi. Throttle slides for engine control.

Ignition: car was originally raced with a Bosch twin-point distributor, later Lucas Opus and now Scorcher with reluctor in the distributor

Lubrication: pressure and scavenge pumps in the sump interconnected with short shaft, driven from the crank. Oil tank external

Crankshaft made by Crankshaft Rebuilders, Forged pistons by Special Pistons Services, Connecting rods made by Argo, NSW.

Capacity: 4.2 litre ‘Indy’ version Bore: 96mm Stroke 71.9mm

Capacity: 4.8 litre as raced by Matich in 1969: Bore 96.5mm, Stroke 82mm

Capacity: 5 litre Nigel Tait built: Bore 96.5mm Stroke 86mm

Chassis: Tubular steel spaceframe: Weight 38 kilograms (bare frame)

Suspension: Front; Lower wishbone, upper camber arms with radius rod. Rear; Reversed lower wishbone with upper camber arm and upper and lower radius rods. Shock absorbers: now Armstrong but raced originally with double-adjustable Koni’s

Steering: Matich manufactured rack and pinion, cast by CAC. Uprights: Matich design and manufactured, steel fabrications

Brakes: Girling, 3 pots per wheel

Wheels: Matich design cast magnesium, front 10.5 by 15”, rear 17” by 15”

Tyres: Avon, front 10.5” by 23” by 15”. Rear 15” by 26” by 15”

Track: front 57”, rear 60”, wheelbase 90”

Body: Fibreglass, manufactured by JWF in Sydney.

How competitive would the SR4 Repco have been in the 1968 Can Am Series?…

In ’67 the dominant McLaren M6A weighed 590Kg/1300lbs and was powered by a 6 litre 530bhp Chevy, the ’68 M8A by a 7 litre 620bhp alloy block Chev, the car weighed circa 1350lbs.

On the face of it FM’s ‘760 Series’ 5 litre, 4 valve, DOHC Repco V8 toting about 580 bhp, the car quoted at 1361lbs would have been ‘in the hunt’. Certainly in relative terms SR4 would have been more competitive than the ‘620 Series’ 4.4 litre, 2 valve, SOHC 400bhp powered SR3 was in 1967.

Whilst the Repco V8 was giving away some power to the Chev, the car similar in weight to M8A, the Matich was potentially a better handling car than M8A given the distribution of the weight. The Repco alloy V8 weighed about 380lbs, the Chev lump circa 550lbs. There was no question about the handling of the Matich cars; ask Chris Amon who’s beautiful handling P4/CanAm 350 Fazz V12 was beaten by Matich in SR3 soundly on every occasion they met during the Australian Tasman rounds in the summer of ’68.

The engines had to last the 200 miles of a CanAm event of course, the Repco ‘860 Series’ F1 engines having major problems in 1968, mainly valve gear related. RBE Project Engineer Norman Wilson’s account of the engine problems in F1 in 1968 is as follows; ‘On a visit to Cosworth after the 860 engine problems Cosworth partner, Mike Costin, said that he realised what our problem was with the valve gear, that it was torsional vibration’.

‘This is where the project started to get unravelled. Frank (Hallam, GM of Repco Brabham Emgines) had sort of admitted the problem but at the time i think Frank had just about left, and Charlie Dean who replaced him wouldn’t understand that the problem was a torsional vibration problem. It was wrecking the cam followers. And the solution to the problem was fairly simple. All we had to do was modify the cam drive like the Cosworth Ford DFV engine and we could have fixed it’.

‘What happens is at certain speeds the front of the camshaft will tend to go a little bit like a tuning fork and as it rotates this front of the crankshaft oscillates back and forth and this oscillation is transferred up through the timing gears. It was making two of the camshafts do the same thing. So when the cam lobes were going around they were ruining the cam followers. The Cosworth has a little spring gizmo in the first timing gear to absorb this so it is not transmitted through the whole system. And Frank realised we needed something like this and we were working on doing that when Charlie Dean arrived on the scene and said it was a lubrication problem.’ This was after the end of the 1968 F1 season mind you, Hallam resigned after Deans arrival, after that disastrous season.

The ‘760 Series’ 4.2 litre, 4 valve, DOHC Repco V8 Indy variant with the same block and heads as the 5 litre finished the Indy 500 in 1969, Peter Revson’s Brabham BT25 finished 5th in the race won by Andretti’s Hawk Ford. Critically, Peter Revson took the only international win for a ’60 Series’ engine when we won the Indianapolis Raceway Park road event in his Brabham BT25 Repco on 27 July 1969.

None of these engines were fitted with the torsional vibration damper or spring gizmo to which Wilson refers. Its said the the bigger ‘760’ engines were simply not revved as hard as their F1 liddl’ ‘860’ brother thereby avoiding the oscillation rev range which was problematic.

For Australian enthusiasts a great ‘mighta been’ is how FM would have gone against the mighty papaya ‘Big Macs’ in 1968?…

Would the SR4 have been quick? You betcha, much faster than SR3. Would the ‘760 Series’ engine have finished 200 mile races? Yes again if the similar Indy variant results in ’69 are a guide. Could SR4 have achieved CanAm podiums in ’68?, probably yes.

Could he have won a race? Maybe, if the planets were aligned noting that year the ‘dynamic duo’ didn’t win two rounds; John Cannon took a great victory in the wet in an old M1B McLaren at Laguna and Mark Donohue at Bridghampton in the Penske M6B when both Bruce and Denny had major engine failures. Could FM have prevailed at these events? Sure, SR4 was quick enough to knock both car/driver combinations off.

‘If yer Aunty had balls she’d be yer Uncle’ of course, ifs, buts and maybes mean nothing in motor racing, as in life. The chassis was late. The engine was late. FM didn’t contest the ’68 CanAm and as a result we were all deprived of seeing Matich take on Bruce, Denny and the rest of the CanAm circus all of whom he knew and respected well.

So Frank raced the car in Oz in ’69, crushed the local opposition and then moved into F5000 supported by Repco…

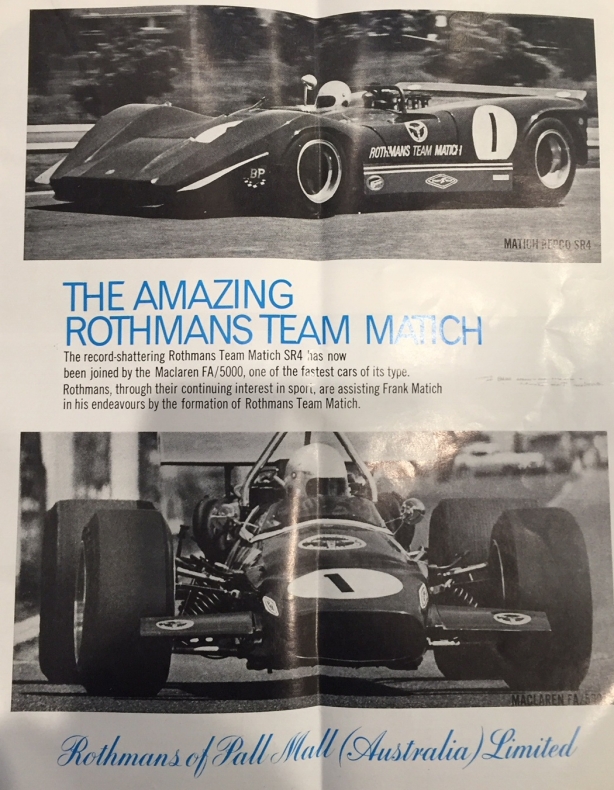

Rothmans brochure featuring both the old, SR4 Repco and the new, McLaren M10A Chev F5000 in 1969 (Tony Johns via Nigel Tait)

The obvious question is, having missed the ’68 series why didn’t the car contest the 1969 CanAm instead of being ‘King of The Kids’ in Oz?..

The answer is simple, the Repco Brabham engine program was over, Jack raced a Cosworth DFV in F1 in 1969, the final races in that partnership the Indy races in 1969.

The Repco board decided to close down Repco Brabham Engines Pty. Ltd, there is no certainty Repco would have committed to F1 in 1969 even had Jack wanted them to. Cost was a big issue for Repco throughout 1968, the failure of the engines that year made it easier to withdraw, particularly given the sort of investment which would have been needed to match the reliability and power of the Ford Cosworth DFV. Its impotant to remember that Rindt put ‘860 Series’ F1 powered Brabhams on pole twice in ’68. The 3 litre ‘860’ Repco was potent! With further development there is no reason the ‘860’ F1 engine could not have won races, it proved its speed in Rindts hands in ’68 if not its reliabilty. And every Tom, Dick and Harry raced DFV’s in ’68; McLaren, Lotus and Ken Tyrrell’s Matra International team, pole amongst that lot was an achievement, the Ferrari’s also quick that year.

So, whilst Repco were happy to provide Matich with an engine, they would not back an assault in the US with the resources required. Matich employed ex-Repco engineer John Mepstead to look after SR4 during ’69, he wasn’t provided by Repco. Matich didn’t have the funds to race in the US and had already acquired an M10A Chev McLaren F5000 car in advance, well in advance of CAMS decision to agree the next ANF1 as F5000. 2 litre F2 was the alternative.

There was some ‘dogs bollocks’ from the Matich camp at the time about ‘multi-valve’ engines not being legal in the ’69 CanAm which is rubbish, obfuscation. Count the number of Ferrari’s alone which ran that year, the last time i looked they weren’t powered by pushrod OHV V8’s.

Repco’s commercial interests were best served, they quite rightly believed, by building an F5000 variant of the 5 litre Holden V8 to participate in this rapidly growing category. The engine was an immediate success, Matich won the 1970 Australian Grand Prix in a McLaren M10C Repco that November.

There was not the funds to race an SR4 ‘Stateside, customer F5000 engines were a better commercial proposition for Repco and so an interesting and immensely successful, Repco Brabham Engines Pty. Ltd. chapter of Repco history ended, with a big, quad cam 5 litre bang mind you!

As an aside the last championship won by an RBE engine was Henry Michell’s victory in the 1974 Australian Sportscar Championship aboard an Elfin 360 powered by an ex-Tasman RBE ‘730 Series’ 2.5 litre V8…

The SR4’s 1969 Australian Competitor Set…

The sinfully sexy, wedgy, state of the art, but oh-so-twitchy Elfin ME5 Chev of Niel Allen at Warwick Farm in 1969, below.

Garrie Cooper’s latest big car had a nice, stiff aluminium monocoque chassis but the short wheelbase device, even with Allen at the wheel, very much Matich’s equal in F5000 was never a winning car and with only 480bhp was ‘gutless’ compared to Matich’s 580! Never thought i would say that about a 5 litre injected Chev!

Bob Jane below in the sensational McLaren M6 Repco at Hume Weir in 1969, le patron at the wheel of the car raced mainly by John Harvey including the Australian Sportscar Championship in 1971/2. Also Repco powered but ‘only’ an SOHC 5 litre ‘740 Series’ V8, Harvey was very much an ace but the car not on the same page as Matich’s beastie. Its time would come…but only after SR4 was popped away as a museum piece within months of its championship win.

Don O’Sullivan in the hi-winged Matich SR3 ‘3’ Repco slicing into Warwick Farm’s Esses in early 1969. Behind him is Niel Allen in the ex-Matich Elfin 400/Traco Olds, now 5 litre Chev engined car. The chassis of the SR3 was either identical to or very, very similar to Cooper’s Elfin 400 design.

Matich Cars: The Chassis List…

Matich listed ‘his cars’ by chassis number as below. After discussion with Frank Matich, Darryl Duff who owned one of the SR3’s at the time in the early eighties prepared a document listing ‘Franks’ sportscars. A truncated summary of it is set out below. To that I have added Matich’s single-seaters, all F5000’s the source, Derek Kneller, his engineer/mechanic throughout the entire F5000 period;

Matich in SR3 ‘3’ Repco ‘620 Series 4.4 litre V8, the last one built, at Warwick Farm in 1968, this is the chassis with which he belted Chris Amon in the ’68 Tasman support rounds, Amon in David McKays/Scuderia Veloce Ferrari P4/Can Am 350 (Dick Simpson)

1.Sports Cars: All of multi-tubular spaceframe construction

#1 Lotus 19B Climax: (the second of FM’s 19’s, highly modified with many Brabham bits and ultimately destroyed in FM’s big ’65 Lakeside shunt)

#2 Elfin 400 Olds: (aka ‘Traco Olds’ first raced Sandown early ’66, still exists)

#3 SR3 (1) Olds/Repco (still exists) Built with 5 litre Traco/Olds, ZF 5 DS-25 ‘box

First race Warwick Farm early ’67, won ’67 Victorian (Sandown) and NSW (Catalina Park) sportscar championships and Australian Tourist Trophy at Surfers Paradise. To Marvin Webster, California, sans engine in June 1967. Tony Settember raced the car for Webster.

#4 SR3 (2) Repco (still exists) RBE ‘620 Series’ 4.4 litre V8 # ‘RB620E22’, from late 1969 Traco/Olds 5 litre from ex-SR3 (1), ZF DS25 ‘box

Built, sold and exported to Kent Price, California US, first raced 3 September 1967, Road America, Elkhart Lake by Matich. Its only US race. Returned to Oz, it was sold on Price’s behalf, by Matich to Malcolm Bailey in 1969. Bailey fitted the ex-Elfin 400/Traco Olds/ SR3 (1) V8 from Niel Allen to the car.

#5 SR3 (3) Repco (still exists) RBE ‘620 Series’ 4.4 litre V8 engine # ‘E25’, ZF 5 DS-25 ‘box

First race by Matich, 17 September 1967 Bridghampton, raced in Oz later in ’67. Won RAC Trophy and Australian Tourist Trophy at Warwick Farm and Mallala respectively in 1968. This is the chassis which beat Amon’s Ferrari P4/CanAm 350 throughout the ’68 Tasman support races. Sold to Don O’Sullivan late in ’68

#6 SR4 Repco: (still exists, ’68 intended CanAm contender, late, only raced ’69 in Oz, won ASSC that year)

#7 SR4B Ford/Lotus twin-cam (still exists, customer car built for John Wood)

2.F5000’s: All aluminium monocoques

Note The Matich Team reskinned their McLaren M10B Repco tub after its Oran Park 1971 practice shunt, their first monocoque experience. Six virtually identical tubs were built by Matich/Commonwealth Aircraft Corporation and built up as follows;

#8 A50 Repco Chassis # ‘001/002’ (1971 AGP and 1972 Gold Star winner, still exists)

#9 A50 Ford # ‘003’ (exported to the US, bits incorporated in sportscar) 1972

#10 A50 Repco # ‘004’ (customer car, John Walker ’73 US L&M later to Jon Davison, still exists)

#11 A51 Repco # ‘005’ (US ’73 L&M Series sold to J Goss, converted to A53 spec, ’76 AGP winner, still exists)

#12 A51/52 Repco # ‘006’ (US L&M Series as A51 converted to A52 spec back at Brookvale in time for the Surfers Gold Star round that September, destroyed in a Warwick Farm testing accident shortly thereafter driven by Bob Muir, scrapped)

#13 A53 Repco # ‘007’ (’74 Tasman car sold to J Goss after FM retirement, still exists)

On the basis of the above the Matich Team built 11 cars; the list above less the Lotus 19B and Elfin 400 which were built in Cheshunt, London and Edwardstown, Adelaide respectively.

FM’s logic of including the Lotus and Elfin as ‘his cars’ is not spelt out in Duff’s document but I suspect FM’s thinking was that he modified the cars to such an extent that they were more ‘Matich’ than Lotus/Elfin which may be true of the Lotus but ‘praps not the Elfin… Both these cars are covered in my ‘Elfin 400’ article the link of which is early in this article.

In Period Race Footage…

SR3.

SR4.

Shot below by Dale Harvey and is at Catalina Park in the Blue Mountains, not Warwick Farm.

Etcetera…

1970 shot of FM in natty check strides, Vicki Fry and journalist and later motor racing publisher, Chevron Group founder Ray Berghouse. Hewland box missing, nice shot of suspension detail (Ray Berghouse)

Special Thanks…

To Nigel Tait for entrusting me with his manuscript

Derek Kneller for his recollections of the 1969/70 period at Team Matich

Credits…

Nigel Tait Collection, Dick Simpson, oldracephotos.com, Repco Ltd, Dave Friedman Collection, Ian Pope, Jay Bondini, The Roaring Season, Derek Kneller, Dale Harvey, Peter Ellenbogen, Stephen Dalton Collection, Ray Berghouse

Tailpiece: Matich is his local ‘backyard’, aboard the SR4 Repco, Warwick Farm’s Esses, now ‘Bell Star’ equipped, 1970…

Finito…